|

Feeler Fv 1500 Vmc

Feeler Fv 1500 Vmc Specification

- Product Type

- Vertical Machining Center (VMC)

- General Use

- CNC Metal Cutting, Milling, Drilling

- Material

- Cast Iron, Structural Steel

- Type

- VMC

- Capacity

- 1500 kg (Max Table Load)

- Weight (kg)

- 9500 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 15 kVA

- Rigidity

- High

- Voltage

- 380 V / 3 Phase

- Motor

- Main Spindle Motor: 15 HP

- Table Size

- 1700 x 700 mm

- Spindle Speed

- 50-8000 RPM

- Axial Choice

- 3 Axis

- Dimension (L*W*H)

- 3000 x 2500 x 2850 mm

- Feature

- High Performance, Precise, Durable

- Color

- White-Grey

- Coolant System

- Standard

- Travel (X/Y/Z Axis)

- 1500 x 700 x 650 mm

- Lubrication System

- Fully Automatic

- Repeatability

- ±0.003 mm

- Rapid Traverse Rate (X/Y/Z)

- 24/24/20 m/min

- Tool Magazine Capacity

- 24 Tools (Arm Type)

- Maximum Tool Diameter

- Ø 100 mm (adjacent), Ø 150 mm (without adjacent)

- Controller

- Fanuc / Mitsubishi / Siemens (as per order)

- Floor Space Required

- 3500 x 3200 mm

- Net Weight

- 9500 kg

- Minimum Input Air Pressure

- 6 kg/cm²

- Spindle Taper

- BT40

- Automatic Tool Changer (ATC)

- Standard

- Positioning Accuracy

- ±0.005 mm

About Feeler Fv 1500 Vmc

*FEELER FV 1500 VMC*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 1525 x 760 x 650 mm

YEAR OF CONSTRUCTION : 1998

Reference No: 3261

Video Link: https://youtu.be/1vCWnItaHcY

Technical Specifications:

WORKING CAPACITY

Table Size: 1700 x 750 mm

Travels (XYZ): 1525 x 760 x 650 mm

Guideways: LM

Spindle Nose to Table Surface: 150 - 810 mm

Max. Table Load: 1500 Kgs

CNC

Control: Fanuc OM (Alpha Drives)

SPINDLE

Spindle Taper: BT50

Spindle Speeds: 6000 RPM

ATC

Tool Changer (Arm Type): 24 Stations

DIMENSIONS

Floor Space: 3720 x 4150 mm

Max. Machine Height: 3200 mm

Machine Weight: 12 T

Exceptional Precision and Reliability

With positioning accuracy of 0.005 mm and repeatability of 0.003 mm, the Feeler Fv 1500 VMC delivers high-precision machining consistently. Its robust structure ensures stability even during demanding operations, making it ideal for intricate milling and drilling applications requiring exact tolerances.

Advanced Automation for Enhanced Productivity

Featuring a standard automatic tool changer (ATC) with a 24-arm type magazine, the Feeler Fv 1500 VMC maximizes operational efficiency. Rapid traverse rates of up to 24 m/min (X/Y) enable faster cycle times, while fully automatic lubrication and coolant systems ensure smooth, uninterrupted production.

Versatile Controller Options and User-Friendly Interface

Customers can choose from Fanuc, Mitsubishi, or Siemens controllers based on their preferences or existing infrastructure. PLC control and computerized automation simplify complex milling and drilling tasks, providing operators with intuitive, efficient machine management.

FAQ's of Feeler Fv 1500 Vmc:

Q: How does the automatic tool changer (ATC) improve the productivity of Feeler Fv 1500 VMC?

A: The ATC system holds up to 24 tools in an arm-type magazine, allowing swift and automatic tool changes during operation. This reduces manual intervention and setup time, thereby enhancing overall machining speed and increasing productivity.Q: What applications is the Feeler Fv 1500 VMC best suited for?

A: This VMC excels in CNC metal cutting, milling, and drilling tasks. Its high rigidity, precise position control, and strong table load capacity make it ideal for manufacturing industries dealing with complex metal components.Q: When is it recommended to use the maximum tool diameter of 150 mm in the magazine?

A: The maximum tool diameter of 150 mm can be used when the adjacent tool pockets are left empty, ensuring safe clearance. For operations where adjacent pockets are filled, the recommended diameter is 100 mm to prevent collision and maintain tool integrity.Q: Where can the Feeler Fv 1500 VMC be installed, considering required floor space and installation needs?

A: A minimum floor space of 3500 x 3200 mm is recommended to accommodate the machine and allow safe movement around it. The site should also provide stable electric supply (380V/3 Phase) and a minimum air pressure of 6 kg/cm2.Q: What is the process for controller selection when ordering this VMC model?

A: Customers can specify their preferred controller brand-Fanuc, Mitsubishi, or Siemens-during the ordering process. This flexibility allows integration with existing plant control systems and user familiarity, ensuring efficient setup and operation.Q: How does the machine's robust construction benefit long-term usage?

A: Made from cast iron and structural steel, the Feeler Fv 1500 VMC provides high rigidity and durability. This solid build minimizes vibration, enhances machining accuracy, and supports reliable performance over prolonged and intensive production cycles.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Xyz Krv 2000 Cnc M1tr Turret Milling Machine

Minimum Order Quantity : 1 Number

Material : Other, Cast Iron & Steel

Type : Other, Turret Milling Machine

Power Source : Electric

Voltage : 415 V

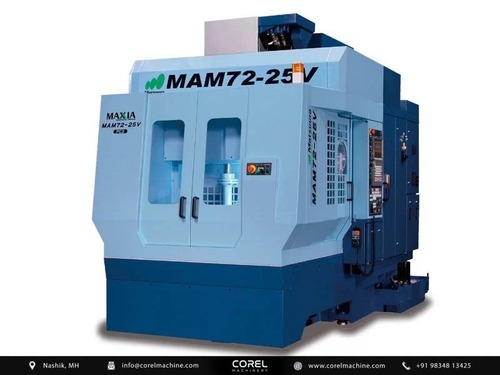

5-axis Matsuura Mam72-25v Vmc (Transit)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Other, Cast Iron Structure, Suitable for Machining Metals

Type : Other, CNC Machining Center

Power Source : Electric

Voltage : 400V, 3 Phase

Yang Smt 500 Drill Tap Center (2 Off)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Other, Cast Iron Body

Type : Other, CNC Drill Tap Center

Power Source : Electric

Voltage : 220/380 V, 3Phase

Mori Seiki Mv 65 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Other, Cast Iron (Bed), Steel Components

Type : Other, Heavy Duty CNC VMC

Power Source : Electric

Voltage : 380415V

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |