|

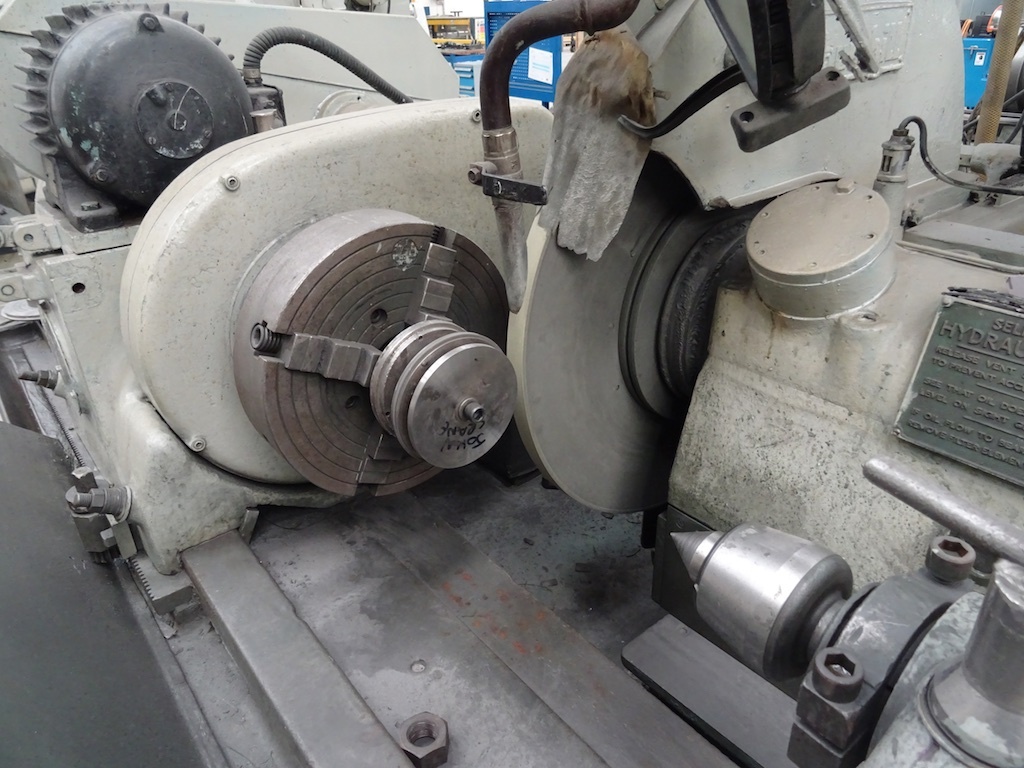

Churchill Cylindrical Grinder

Churchill Cylindrical Grinder Specification

- Product Type

- Cylindrical Grinder

- General Use

- Industrial Metal Grinding

- Material

- Steel & Cast Iron

- Type

- Universal

- Capacity

- Swing over table: 400 mm, Distance between centers: 1600 mm

- Weight (kg)

- Approx. 4000 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 5 HP

- Rigidity

- Heavy Duty Cast Iron Body

- Voltage

- 415V

- Motor

- Three Phase Motor

- Table Size

- 1600 mm x 150 mm

- Spindle Speed

- Variable (Up to 1450 RPM)

- Axial Choice

- Manual & Automatic

- Dimension (L*W*H)

- 3300 mm x 1500 mm x 1400 mm

- Feature

- Precision Grinding, Hydraulic Table Movement

- Color

- Blue & Grey

- Table Travel

- 1600 mm

- Grinding Wheel Size

- 500 mm x 75 mm x 203 mm

- Max Load Between Centers

- 500 kg

- Max Workpiece Diameter

- 400 mm

- Coolant System

- Integrated

- Lubrication System

- Automatic

- Chuck Size

- 200 mm

- Work Head Speed

- Variable

- Center Height

- 200 mm

- Wheel Head Motor

- 5 HP

About Churchill Cylindrical Grinder

*CHURCHILL CYLINDRICAL GRINDER*

CATEGORY : CYLINDRICAL GRINDERS

CAPACITY : 533 x 1800 mm

Reference No: 732

Video Link: https://youtu.be/GjK6fBvvzMQ

Technical Specifications:

WORKING CAPACITY

Between Centers: 1800 mm

Swing: 533 mm

Equipped with

DRO

Precision and Performance

Engineered for industrial metal grinding, the Churchill Cylindrical Grinder offers precision with its variable speed spindle and robust hydraulic table movement. Its heavy-duty cast iron structure ensures minimal vibration, resulting in consistent accuracy during operation.

Advanced Features for Efficient Operation

With an integrated coolant system, automatic lubrication, and variable work head speed, the grinder maintains optimal conditions for prolonged use. The semi-automatic controls and manual/automatic axial choice provide flexibility for various user requirements.

Versatile Capacity and Durability

Capable of handling workpieces up to 400 mm in diameter and 500 kg between centers, the grinder accommodates large components on its spacious 1600 mm x 150 mm table. Its durable steel and cast iron construction support demanding industrial applications.

FAQ's of Churchill Cylindrical Grinder:

Q: How does the Churchill Cylindrical Grinder enhance precision during metal grinding operations?

A: The grinder utilizes a variable speed spindle, hydraulic table movement, and a stable cast iron body, which collectively minimize vibrations and allow for precise surface finishing on steel and cast iron components.Q: What is the maximum size and weight of workpieces that can be processed on this cylindrical grinder?

A: This machine supports workpieces with a maximum diameter of 400 mm, a swing over table of 400 mm, up to 1600 mm between centers, and a load capacity of 500 kg between centers.Q: Where is the Churchill Cylindrical Grinder most commonly used?

A: It is widely used in industrial settings across India for metal shaping, resurfacing, and precision grinding tasks, particularly by exporters, importers, suppliers, and traders in heavy manufacturing sectors.Q: What processes does the integrated coolant and automatic lubrication systems support?

A: These systems keep grinding temperatures low and reduce friction, thereby preventing thermal damage, ensuring smooth operation, and extending the lifespan of internal components and the grinding wheel.Q: When should the grinder's axial mode be switched between manual and automatic?

A: Manual mode is utilized for tasks requiring human intervention or fine adjustments, while automatic mode suits repetitive precision grinding processes, optimizing workflow efficiency.Q: What are the key benefits of using this cylindrical grinder?

A: The main advantages are reliable precision, enhanced durability, efficient operation, ease of control, and suitability for heavy-duty, high-volume industrial grinding applications.Q: How is the Churchill Cylindrical Grinder powered and what is its energy consumption?

A: Powered by a three-phase electric motor running on 415V, the grinder's power consumption is rated at 5 HP, providing ample energy for demanding grinding tasks.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Jones And Shipman 1078 Production Od Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Grinding Outer Diameters of Components

Spindle Speed : 1400 RPM

Feature : Other, Precision Grinding, Rigid Construction

Computerized : No

John Lund Universal Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Industrial Grinding Applications

Spindle Speed : Up to 2800 RPM

Feature : Other, Precision Grinding, Versatile Functions

Computerized : No

Tschudin Htg 412 Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Precision cylindrical grinding

Spindle Speed : Up to 2400 RPM

Feature : Other, Precision Grinding, Compact Design

Computerized : No

Churchill Internal Grinder (Transit)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Grinding internal surfaces of cylindrical or tube components

Spindle Speed : Variable, up to 8000 rpm (depends on model)

Feature : Other, High precision internal grinding, variable speed spindle, robust construction

Computerized : No

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |