|

Abwood Sg4h Cup Wheel Grinder

Abwood Sg4h Cup Wheel Grinder Specification

- Product Type

- Cup Wheel Grinder

- General Use

- Surface grinding of metals and industrial components

- Material

- Cast Iron body with steel accessories

- Type

- Surface Grinder

- Capacity

- Max. job height 160 mm

- Weight (kg)

- Approx. 700 kg

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Power Source

- Electric

- Power Consumption

- 3.0 kW

- Rigidity

- Heavy-duty cast base

- Voltage

- 415 V, 3 Phase

- Motor

- 3 HP Main Motor

- Table Size

- 450 mm x 150 mm

- Spindle Speed

- 2880 RPM

- Axial Choice

- Manual

- Dimension (L*W*H)

- 1100 mm x 950 mm x 1350 mm

- Feature

- High rigidity, precision grinding, adjustable cup wheel

- Color

- Industrial Grey/Blue

- Minimum Feed

- 0.01 mm

- Table Longitudinal Movement

- 450 mm

- Maximum Workpiece Clamping Area

- 430 mm x 150 mm

- Grinding Wheel Size

- 175 mm x 13 mm x 78 mm

- Wheel Head Motor

- 3 HP, 2800 rpm

- Work Table Surface Finish

- Ra 0.8 µ as standard

- Coolant System

- Built-in coolant pump and tank

- Table Cross Movement

- 230 mm

About Abwood Sg4h Cup Wheel Grinder

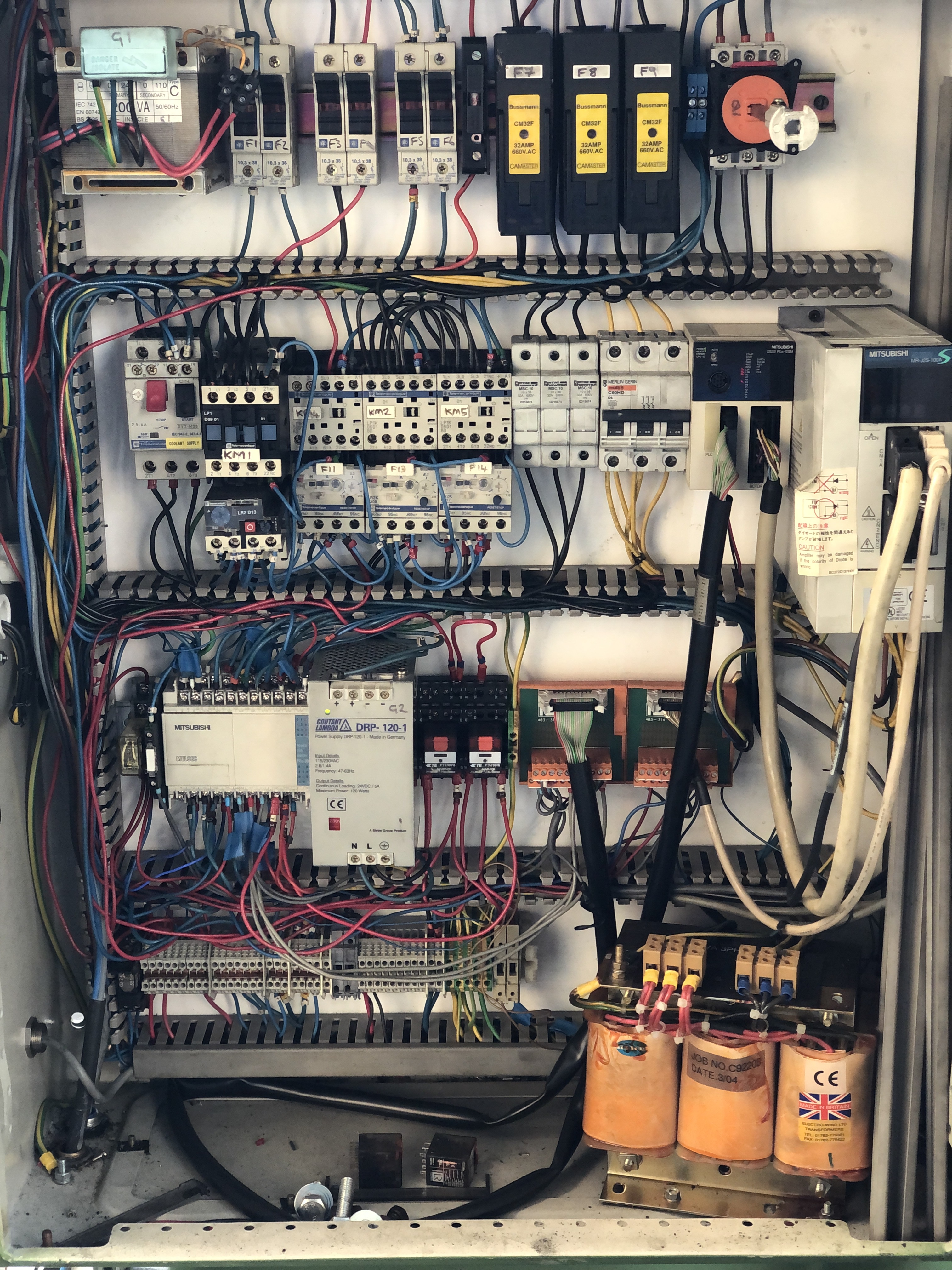

*ABWOOD SG4H CUP WHEEL GRINDER*

CATEGORY : SURFACE GRINDERS

CAPACITY : 500 x 200 x 270 mm

YEAR OF CONSTRUCTION : 2000

Reference No: 1201

Technical Specifications:

Magnetic Chuck: 450 x 200mm,

Max. Working Height: 270mm,

Max. Work Area: 500 x 200mm,

Hydraulic Infeed of Table to Wheel: 0.005 0.025 mm,

Wheel Cylinder Dia: 150-200mm,

Wheel Segmental Dia: 200mm,

Spindle Speed: 2350 RPM,

Spindle Motor: 4k.w.,

Machine Weight: 1.8T,

Coolant through spindle

Engineered for Precision and Durability

Designed with a cast iron body and steel accessories, the Abwood Sg4h delivers high rigidity and accurate grinding results. Its 3 HP motor operates at 2800 rpm for efficient power delivery, while the adjustable cup wheel enables tailored finishing for diverse industrial applications. The robust construction ensures both longevity and consistent high performance.

Convenient and Efficient Grinding Process

With a built-in coolant pump and tank, this grinder minimizes thermal distortion and prolongs wheel life. Users benefit from manual but precise table cross and longitudinal movements, making it suitable for small to mid-sized surface grinding. The minimal feed of 0.01 mm guarantees fine adjustments and superior finishes for all workpieces.

FAQ's of Abwood Sg4h Cup Wheel Grinder:

Q: How should the Abwood Sg4h Cup Wheel Grinder be installed and powered?

A: Installation requires a stable, level surface to accommodate its approximately 700 kg weight. The grinder operates on a 415 V, 3-phase electric supply and should be connected by a qualified electrician to ensure safety and compliance with local electrical standards.Q: What materials and workpiece sizes can the grinder handle?

A: The Sg4h is designed primarily for surface grinding metals and industrial components. It supports a maximum clamping area of 430 mm x 150 mm, a maximum job height of 160 mm, and provides a table size of 450 mm x 150 mm, making it versatile for a variety of mid-sized workpieces.Q: When should the coolant system be used during operation?

A: The integrated coolant pump and tank should be engaged during all grinding operations to minimize heat buildup, prevent workpiece distortion, and extend the life of the grinding wheel. Regular monitoring and topping up of the coolant is recommended.Q: Where is the Abwood Sg4h grinder most effectively utilized?

A: This surface grinder is ideal for use in industrial workshops, tool rooms, manufacturing units, and metal fabrication facilities. Its heavy-duty construction and precise controls make it suitable for professional exporters, importers, suppliers, and traders in India.Q: What is the process for achieving the standard surface finish?

A: To attain the Ra 0.8 surface finish, start by properly clamping the workpiece, then use the manual feed to incrementally advance the table and wheel. Utilize the built-in coolant system and make fine, consistent passes, taking advantage of the 0.01 mm feed capability.Q: What are the main benefits of using this grinder for surface finishing?

A: The Abwood Sg4h offers high rigidity, precision grinding, adjustable wheel positioning, efficient cooling, and minimal vibration. These features combine to deliver superior surface finishes, extend grinding wheel life, and enhance overall productivity in industrial applications.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinders Category

Chevalier Manual Surface Grinder

Minimum Order Quantity : 1 Number

Computerized : No

Axial Choice : X, Y, Z axes

Spindle Speed : 2800 rpm

Weight (kg) : 1000 kg

Jones Shipman 540p Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Axial Choice : Manual/Automatic

Spindle Speed : 2800 RPM

Weight (kg) : 900 kg

Reid 618 Hyd Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Axial Choice : Hydraulic longitudinal, manual/cross

Spindle Speed : 3600 RPM

Weight (kg) : Approx. 800 kg

Waldrich Coburg 30 Fs 3030 Slideway Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Axial Choice : Multiple axis movement (Longitudinal, Cross, Vertical)

Spindle Speed : Up to 1500 RPM

Weight (kg) : Approx. 100,000 kg

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |