|

Cincinnati Cfv 550i Vmc

Cincinnati Cfv 550i Vmc Specification

- Product Type

- VMC (Vertical Machining Center)

- General Use

- Metal cutting, precision machining

- Material

- Cast Iron Base

- Type

- CNC Machining Center

- Capacity

- Max Load 500 kg

- Weight (kg)

- Approx. 5000 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 18 kVA

- Rigidity

- High structural rigidity

- Voltage

- 415 V

- Motor

- Spindle: 7.5/11 kW (Fanuc)

- Table Size

- 1000 mm x 500 mm

- Spindle Speed

- 10000 rpm

- Axial Choice

- 3 Axis (X/Y/Z)

- Dimension (L*W*H)

- 2300 mm x 2620 mm x 2940 mm

- Feature

- High-speed machining, rigid structure, precision engineering

- Color

- White & Blue

- Rapid Traverse Rate

- 36/36/30 m/min (X/Y/Z)

- Tool Magazine Capacity

- 24 Tools (ATC)

- Coolant System

- Equipped

- Chip Conveyor

- Optional

- Minimum Input Air Pressure

- 5.5 kg/cm2

- Positioning Accuracy

- ±0.005 mm

- Tool Change Time

- 2.5 sec (Tool to Tool)

- Travel (X/Y/Z)

- 550/410/510 mm

- Spindle Taper

- BT40

- Controller

- FANUC/SIEMENS/MITSUBISHI (Options Available)

- Repeatability

- ±0.003 mm

About Cincinnati Cfv 550i Vmc

*CINCINNATI CFV 550i VMC*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 550 x 550 x 550 mm

YEAR OF CONSTRUCTION : 2004

Reference No: 475

Video Link: https://youtu.be/uJsSVE1bTdQ

Technical Specifications:

WORKING CAPACITY

Table Size: 700 x 550 mm

Travels (XYZ): 550 x 550 x 550 mm

Guideways: LM

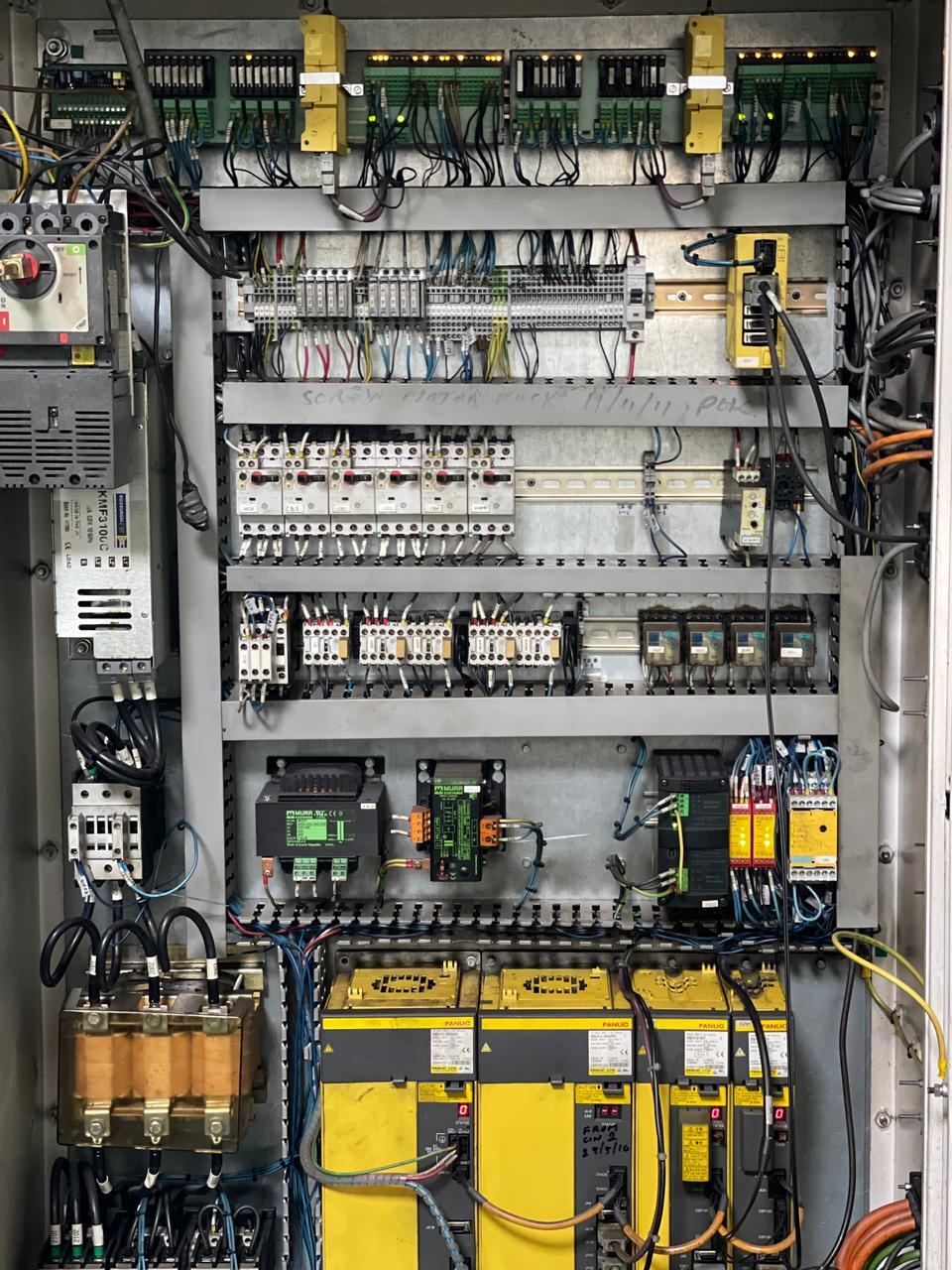

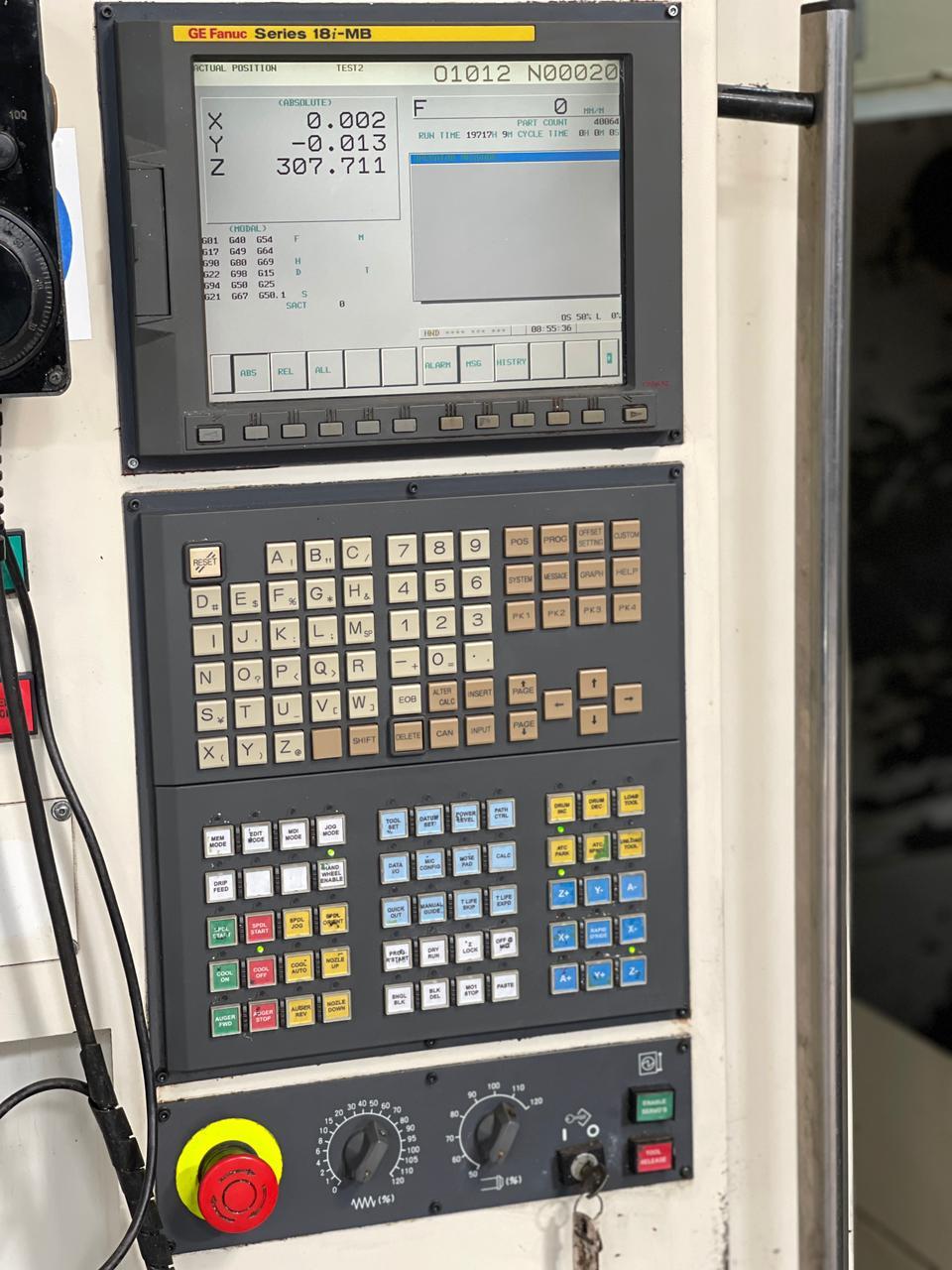

CNC

Control: Fanuc 18i-MB

SPINDLE

Spindle Taper: BT40

Spindle Speeds: 6000 RPM

ATC

Tool Change Capacity: 21 Tools Bi-Directional

Through Coolant Spindle

High Precision Engineering

Engineered for superior accuracy, the CFV 550i delivers a positioning accuracy of 0.005 mm and repeatability of 0.003 mm. Its cast iron base ensures vibration damping and stable machining, making it the optimal choice for high-precision components. The machines rigid structure supports consistent tolerances even during long production runs.

Efficient Tool Management

Equipped with a 24-tool automatic tool changer (ATC) and 2.5-second tool change time, this VMC minimizes downtime and maximizes productivity. The high-speed spindle and efficient chip handling (optional conveyor) support rapid and uninterrupted machining, suitable for high-mix, low-volume to mass production environments.

Versatile Control Options

The CFV 550i offers the flexibility of FANUC, SIEMENS, or MITSUBISHI controllers, providing compatibility with diverse production needs. This adaptability makes it easy to integrate the machine into existing manufacturing setups, enhancing its appeal for exporters, suppliers, and precision engineering workshops.

FAQs of Cincinnati Cfv 550i Vmc:

Q: How does the Cincinnati CFV 550i VMC achieve high precision in machining operations?

A: The CFV 550i maintains high precision using a rigid cast iron base for structural stability, with positioning accuracy of 0.005 mm and repeatability of 0.003 mm. This ensures that even intricate parts are produced within tight tolerances.Q: What are the key benefits of using the CFV 550i for metal cutting and precision machining?

A: Benefits include rapid traverse rates (up to 36 m/min), a robust automatic tool changer, high spindle speeds, and a powerful 7.5/11 kW motor. These features deliver swift cycle times, improved surface finish, and consistent dimensional accuracy.Q: When is it ideal to utilize the optional chip conveyor system with this machine?

A: The chip conveyor is recommended during high-volume or continuous machining tasks. It efficiently removes swarf, reducing manual intervention and ensuring uninterrupted production, especially when machining materials that generate large chip volumes.Q: Where can operators customize the controller options and why is this versatility important?

A: Operators can select from FANUC, SIEMENS, or MITSUBISHI controllers, allowing adaptation to factory standards or specific workflow requirements. This versatility streamlines training and integration with existing shop-floor equipment.Q: What is the process for changing tools on the CFV 550i VMC, and how fast is it accomplished?

A: The automatic tool changer holds 24 tools and switches between them in just 2.5 seconds (tool to tool). This rapid process boosts production efficiency by minimizing downtime during tool changeovers.Q: How is the machine cooled during operation, and what upkeep does the coolant system require?

A: The CFV 550i is equipped with an integrated coolant system, ensuring optimal temperatures during high-speed machining. Operators should regularly check coolant levels and cleanliness to maintain performance and extend tool life.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Xyz Krv 2000 Cnc M1tr Turret Milling Machine

Minimum Order Quantity : 1 Number

Spindle Speed : 70 3600 RPM (Variable)

Voltage : 415 V

Product Type : CNC M1TR Turret Milling Machine

Power Consumption : 3 HP

Matchmaker 700 Cnc Mill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Spindle Speed : 60 8000 rpm

Voltage : 380V

Product Type : CNC Milling Machine

Power Consumption : 8 kW

5-axis Matsuura Mam72-25v Vmc (Transit)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Spindle Speed : 20,000 rpm

Voltage : 400V, 3 Phase

Product Type : Vertical Machining Center (VMC)

Power Consumption : 42 kVA

Haas VF-4 VMC

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Spindle Speed : 8100 RPM (standard), 10000 or 15000 RPM (optional)

Voltage : 220/440 V AC

Product Type : Vertical Machining Center (VMC)

Power Consumption : 20 kVA

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |