|

Cincinnati Mk2 Double Spindle Universal Milling

Cincinnati Mk2 Double Spindle Universal Milling Specification

- Product Type

- Universal Milling Machine

- General Use

- Metal Cutting, Industrial Milling

- Material

- Cast Iron, Hardened Steel

- Type

- Horizontal & Vertical Universal Milling

- Capacity

- Heavy Duty

- Weight (kg)

- Approx. 2500 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 5 HP Approx.

- Rigidity

- High

- Voltage

- 415 V

- Motor

- AC Motor

- Table Size

- 54 x 12 (1370 x 305 mm) approx.

- Spindle Speed

- 36 - 1800 RPM

- Axial Choice

- 3 Axis

- Dimension (L*W*H)

- Approx. 2100 x 1600 x 1800 mm

- Feature

- Double Spindle, Universal Head, Rugged Construction

- Color

- Green

- Cooling System

- Fitted

- Longitudinal Travel

- 1000 mm

- Table Feed

- Automatic

- T Slots

- 3

- Vertical Travel

- 420 mm

- Milling Head Tilt

- 45°

- Number of Spindles

- 2 (Double Spindle)

- Main Application

- Gear Cutting, Slotting, Drilling

- T Slot Size

- 16 mm

- Max Table Load

- 400 kg

- Cross Travel

- 340 mm

About Cincinnati Mk2 Double Spindle Universal Milling

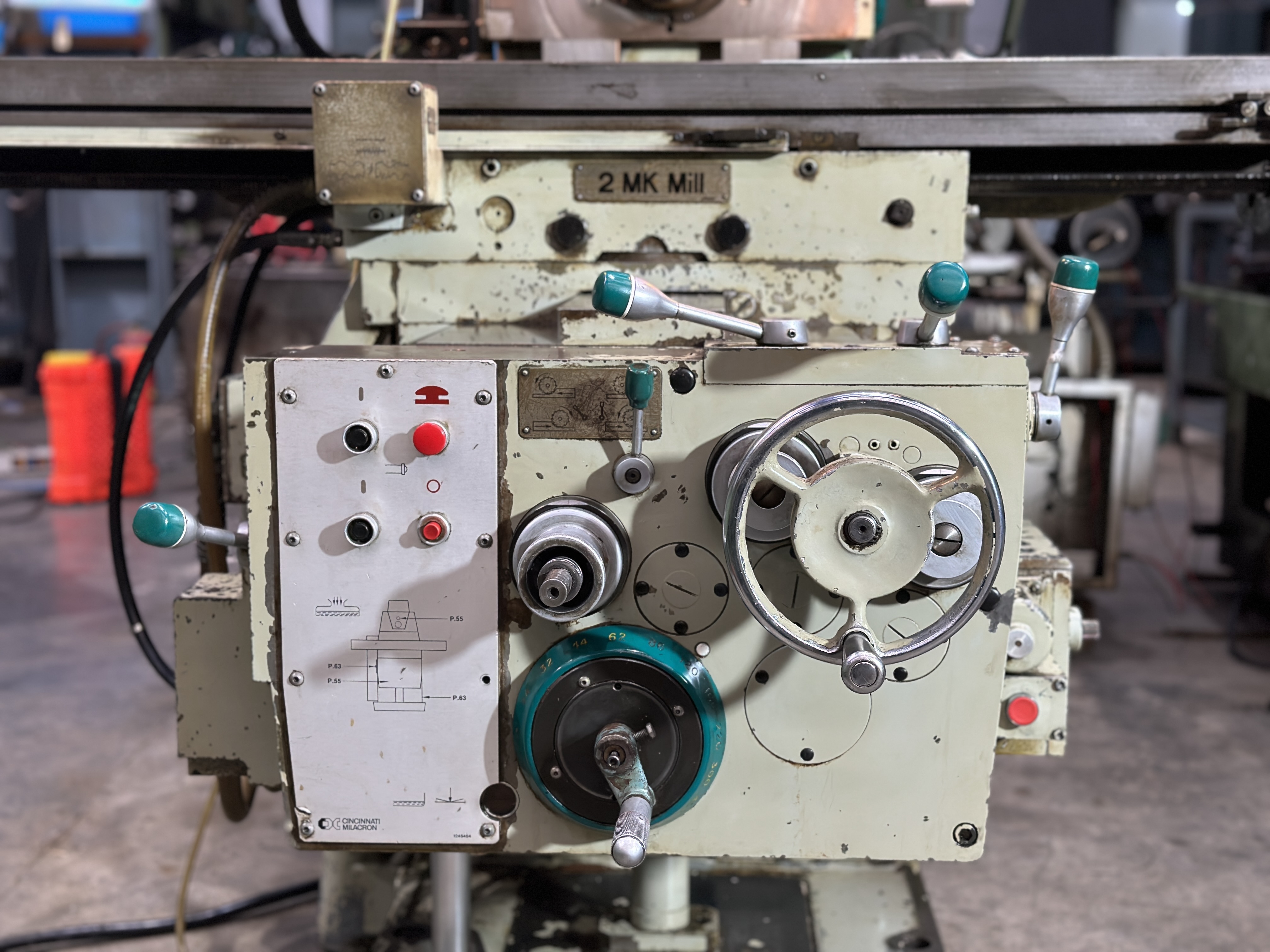

*CINCINNATI MK2 DOUBLE SPINDLE UNIVERSAL MILLING*

CATEGORY : MILLING MACHINES

CAPACITY : 1500 x 350 mm

Reference No: 3701

Video Link: https://youtu.be/FG-gPoKTtfM

Technical Specifications:

Table: 1500 x 350 mm

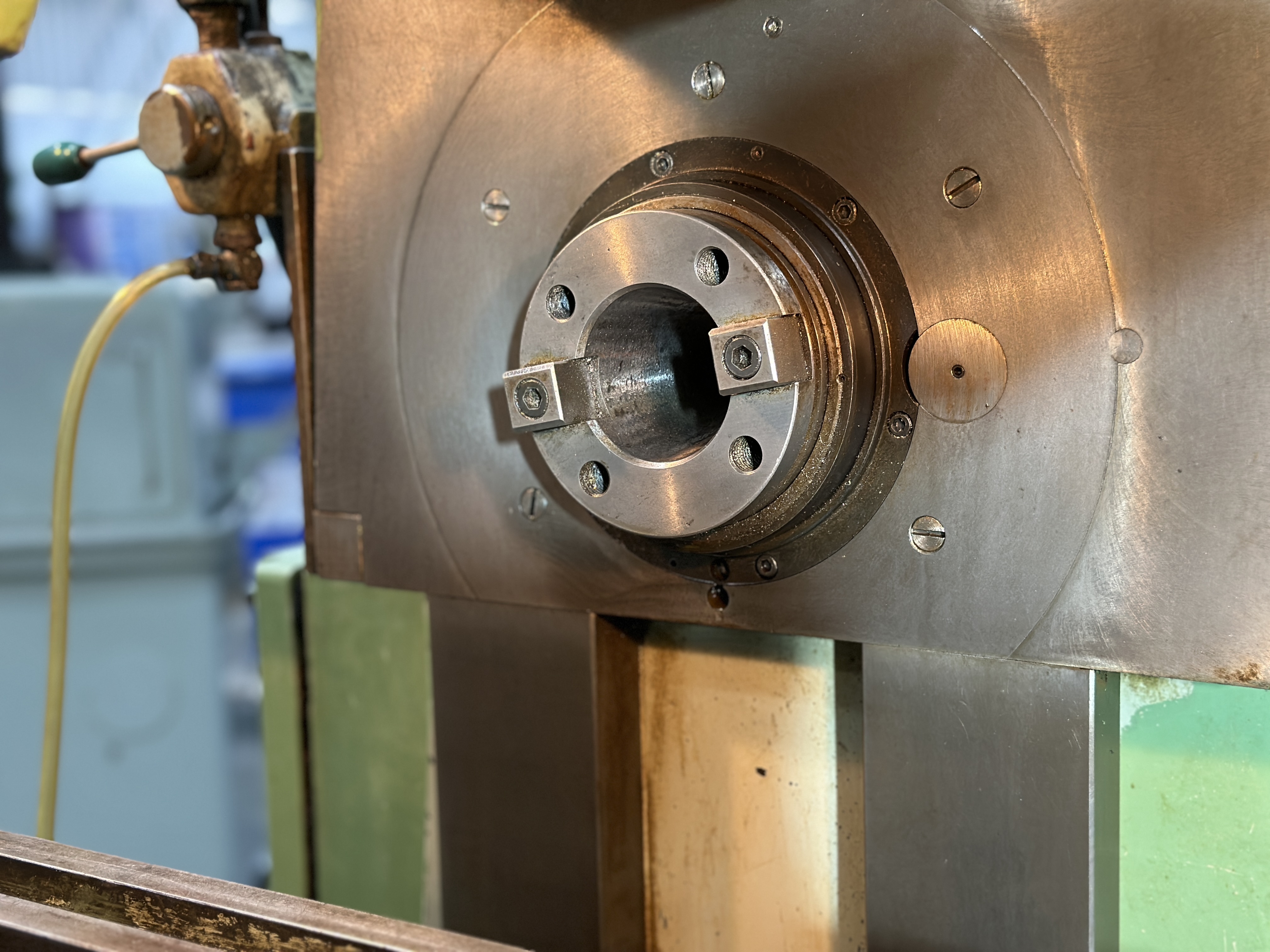

ISO 50 Taper

Double Spindle

Swivel Table

Double Spindle Design for Higher Productivity

With two independently driven spindles, the Cincinnati Mk2 enables efficient metal milling by allowing simultaneous or sequential operations. This double spindle setup streamlines complex tasks such as gear cutting and slotting, significantly reducing processing time and increasing output for industrial applications.

Rugged Construction and Universal Milling Capability

Manufactured from cast iron and hardened steel, the machine features high rigidity and a universal head that tilts 45, offering stability for heavy-duty longitudinal, cross, and vertical milling operations. Its semi-automatic control and universal design support both horizontal and vertical milling, accommodating a wide array of industrial requirements.

Precision and Ease of Use for Industrial Settings

The automatic table feed, fitted cooling system, and 3-axis choice facilitate precise, uninterrupted operation even during prolonged usage. High spindle speed range (36-1800 RPM) and heavy load capacity (up to 400 kg) ensure adaptability for various machining processes on different materials.

FAQ's of Cincinnati Mk2 Double Spindle Universal Milling:

Q: How does the double spindle feature benefit industrial milling tasks?

A: The double spindle setup allows operators to perform two machining processes either simultaneously or as sequential operations without changing the setup. This enhances productivity and minimizes downtime, making it highly efficient for tasks like gear cutting and multitasking on heavy components.Q: What types of materials can be processed with the Cincinnati Mk2 Universal Milling Machine?

A: This machine is engineered for heavy-duty operations and works efficiently on cast iron, hardened steel, and various other metals, making it suitable for industrial-grade applications and robust metal components.Q: When should I utilize the automatic table feed function?

A: The automatic table feed is designed for precision and consistency during lengthy milling operations. It is especially useful for tasks requiring uniform movement and accuracy, such as slotting and gear cutting.Q: Where is the Cincinnati Mk2 Milling Machine commonly used?

A: This milling machine is popular in metalworking industries, manufacturing units, and machining workshops across India. It is suitable for exporters, importers, suppliers, and traders needing reliable, heavy-duty, and versatile equipment.Q: What is the process for adjusting the milling head tilt?

A: The milling head of this machine can be tilted up to 45, allowing for angled or complex milling operations. Adjustment typically involves loosening the locking mechanism, setting the desired angle, and securely re-locking before operation to ensure stability during cutting.Q: How do the machine's features improve its usage for gear cutting and slotting?

A: The universal milling head, high rigidity, double spindle configuration, and long travel ranges provide stability and flexibility for precise gear cutting and slotting. The heavy load capacity and robust construction further support intricate and demanding machining tasks.Q: What are the benefits of the fitted cooling system during extended operation?

A: The integrated cooling system helps dissipate heat generated during prolonged machining, protecting both the workpiece and cutting tools from thermal damage. This ensures consistent accuracy, extends tool life, and maintains the quality of the milled components.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

G.dufour Vertical/horizontal Universal Mill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Motor : Other, Main Drive Motor: 3 to 7.5 HP

PLC Control : No

Spindle Speed : 401800 RPM (Stepper pulley)

Type : Other, Universal Mill

Lilian Hvh M1tr Turret Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Motor : Other, 3 HP Main Motor

PLC Control : No

Spindle Speed : Variable, 604200 rpm

Type : Other, M1TR

Tosfa 4 A H Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Motor : Other, 7.5 HP main motor

PLC Control : No

Spindle Speed : 40 2000 RPM (variable)

Type : Other, Horizontal & Vertical

Gambin 11m Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Motor : Other, Main Motor 7.5 kW

PLC Control : No

Spindle Speed : Range 31.5 to 1400 RPM

Type : Other, Horizontal & Vertical Universal

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |