|

Gambin 1m Universal Milling

Gambin 1m Universal Milling Specification

- Product Type

- Universal Milling Machine

- General Use

- Metal Milling, Industrial Fabrication

- Material

- Cast Iron & Steel

- Type

- Manual

- Capacity

- Heavy Duty

- Weight (kg)

- 2000 kg

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 4 HP

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3 Phase Electric Motor

- Table Size

- 1320 x 250 mm

- Spindle Speed

- 40 2000 rpm (Variable)

- Axial Choice

- 3 Axes (X, Y, Z)

- Dimension (L*W*H)

- 1800 x 1700 x 1600 mm

- Feature

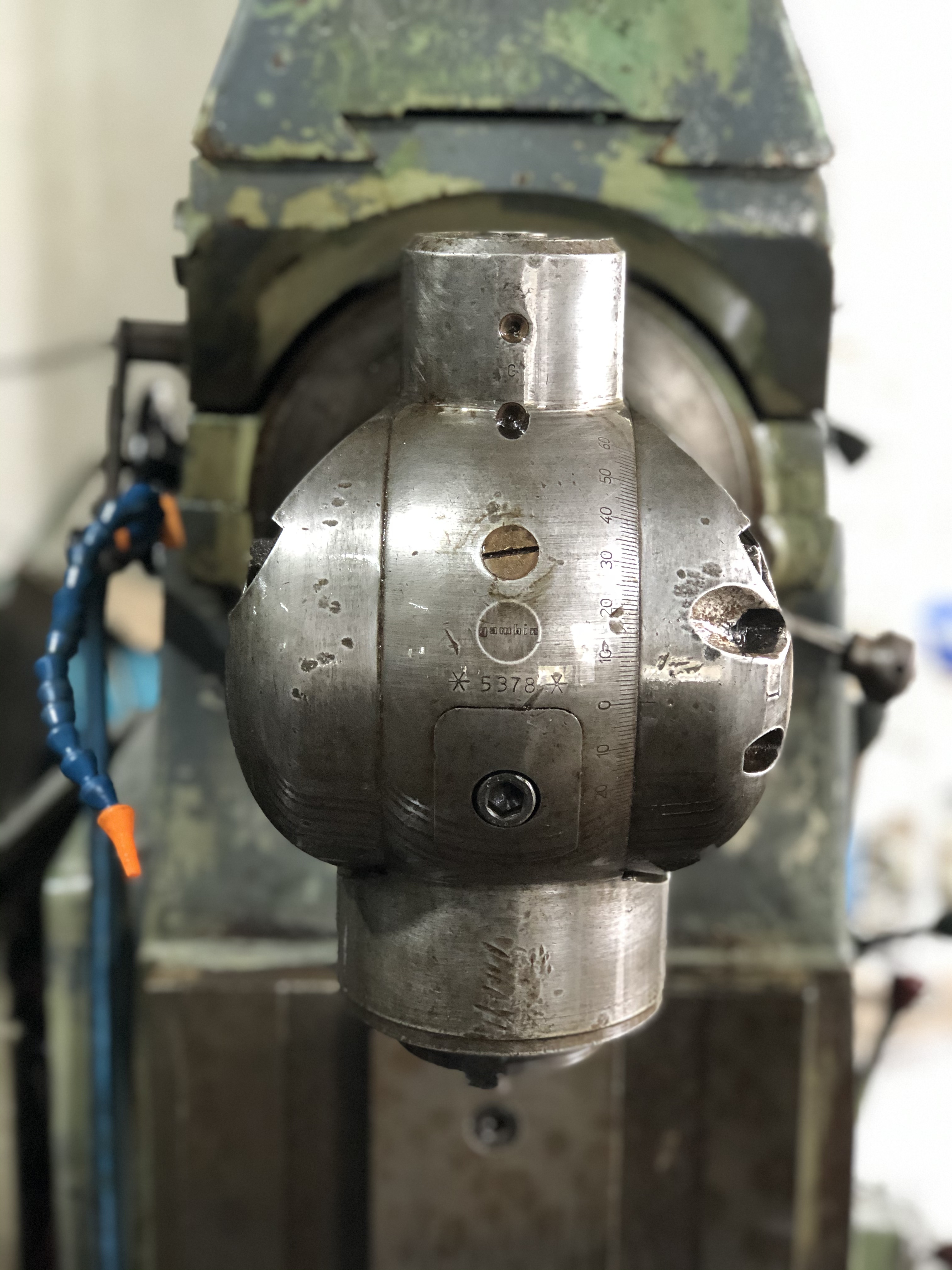

- Universal Swivel Head, Horizontal & Vertical Milling

- Color

- Green & Grey

- T-Slot width

- 14 mm

- Max. Milling Cutter Diameter

- 125 mm

- Longitudinal Traverse (X)

- 800 mm

- Distance from Spindle Nose to Table

- 50 to 450 mm

- Vertical Traverse (Z)

- 400 mm

- Coolant Pump Motor

- 0.15 HP

- Cross Traverse (Y)

- 300 mm

- Number of Feeds

- 32

- Main Spindle Taper

- ISO 40

- Quill Diameter

- 85 mm

- Rapid Feed

- 1200 mm/min

- Distance from Spindle Center to Table

- 0 to 400 mm

- Feed Range

- 22 554 mm/min

- Swivel of Table

- 45

- Overarm Diameter

- 105 mm

- V-belt Section

- B Section

About Gambin 1m Universal Milling

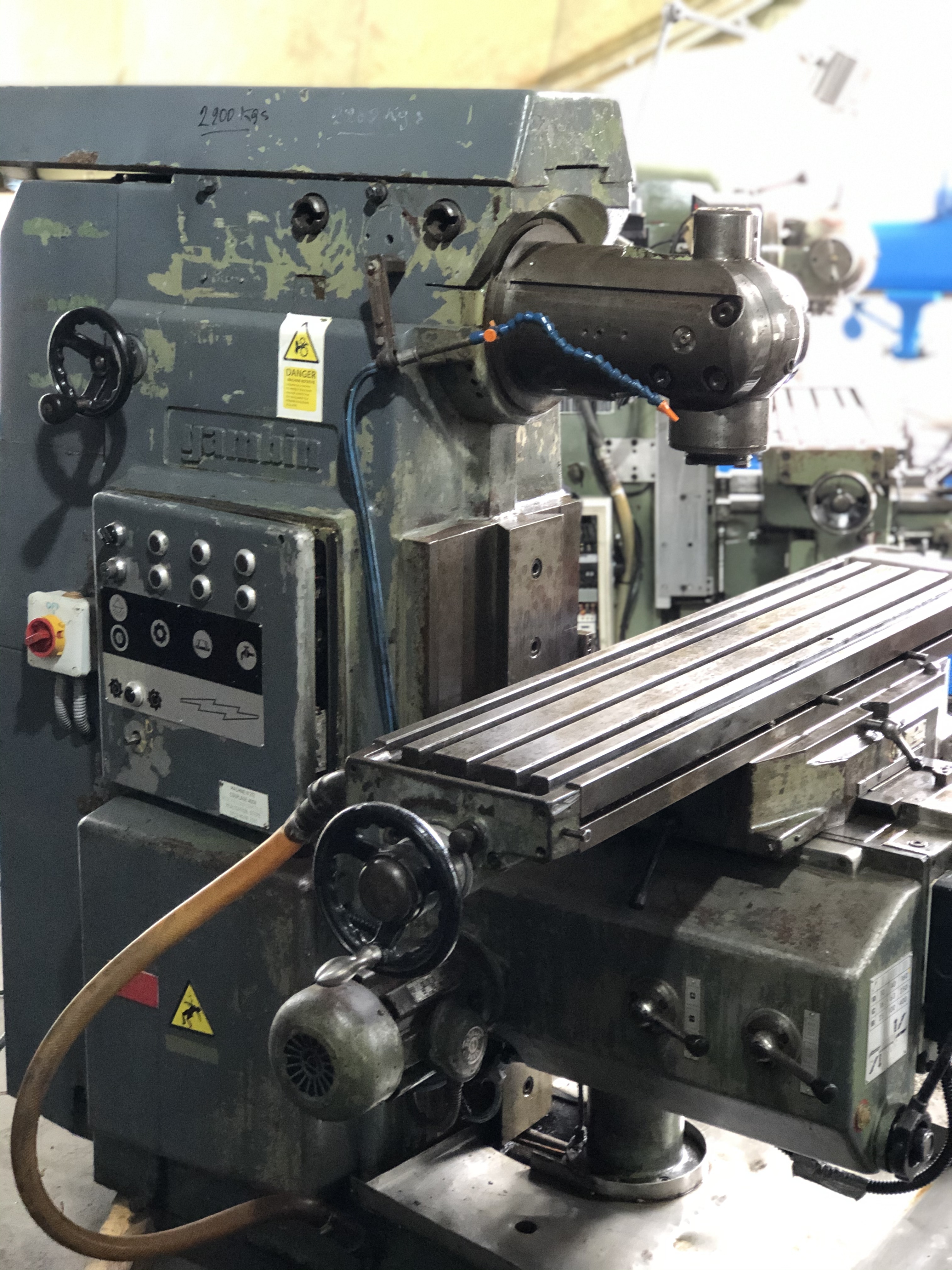

*GAMBIN 1M UNIVERSAL MILLING*

CATEGORY : MILLING MACHINES

CAPACITY : 700 x 400 x 300 mm

Reference No: 585

Video Link: https://youtu.be/_XMTtY1hKQE

Technical Specifications:

Working Capacity

Travels (XYZ): 700 x 400 x 300 mm

Table Size: 1170 x 270 mm

SPINDLE

Spindle Taper: ISO 40

Spindle Speeds: 25 - 1800 RPM

Spindle Head: Double Swivel

Spindle Motor: 4.4 kW

FEED

Feed Speeds: 12 - 630 mm/min

Aprox. Dimensions

Weight: 2.2 T

Dimensions LWH: 1.7 x 2.1 x 1.8 m

Milling Head can be rotated at any angle to do Horizontal, Vertical or Angular Milling

Machine has RAM travel

Versatile Universal Milling Capabilities

The Gambin 1m features a universal swivel head, offering flexibility for horizontal and vertical milling tasks. Its ability to handle a wide range of operations-from shaping and slotting to contouring-makes it a valuable asset for industrial fabrication and toolrooms. The 45 table swivel further expands its usability for complex machining projects.

Optimized for Heavy-Duty Industrial Use

Constructed from premium cast iron and steel, this manual milling machine is built to withstand rigorous use. With a 2000 kg weight and high rigidity, it ensures vibration-free, precise machining. Its 4 HP, 415 V, three-phase motor delivers reliable power for continuous operations, making it ideal for heavy-duty metal milling applications.

Enhanced User Control and Precision

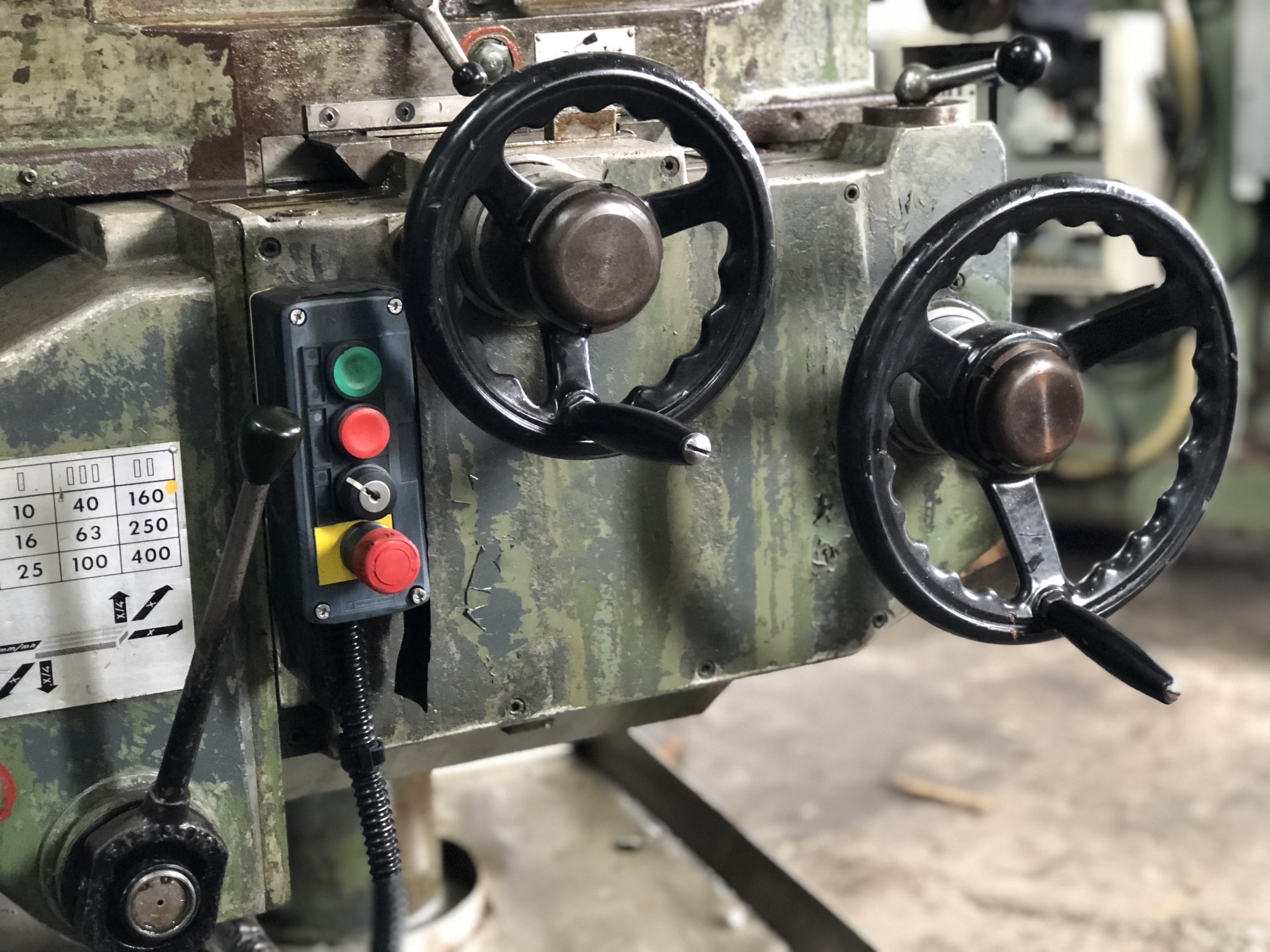

Equipped with a variable spindle speed range of 40 to 2000 rpm and 32 feed options, the Gambin 1m enables operators to tailor settings to specific materials and machining requirements. Manual controls provide full hands-on operation, suitable for producing custom components and prototypes where exacting precision is essential.

FAQ's of Gambin 1m Universal Milling:

Q: How does the Gambin 1m Universal Milling Machine accommodate different types of milling tasks?

A: The Gambin 1m is equipped with a universal swivel head that allows for both horizontal and vertical milling. Its table can be swiveled 45, and combined with the variable spindle speed (40-2000 rpm) and multiple feed options, it is versatile enough for a wide array of metalworking processes, including contouring, slotting, and facing.Q: What are the benefits of the high rigidity and weight of this milling machine?

A: The heavy-duty cast iron and steel construction, along with a substantial weight of 2000 kg, ensures exceptional stability and rigidity. This reduces vibrations during operation, leading to more precise milling, extended tool life, and consistent machining of tough materials.Q: Where can the Gambin 1m Universal Milling Machine be used most effectively?

A: This machine is suitable for industrial fabrication workshops, toolrooms, and metalworking factories, especially where both horizontal and vertical milling capabilities are needed. Its robust build and manual controls make it ideal for heavy-duty applications requiring precise and flexible machining.Q: What type of spindle and taper does the Gambin 1m use, and why is it important?

A: The Gambin 1m uses a main spindle with ISO 40 taper. This industry-standard taper provides strong, secure tool holding, which is crucial for accurate machining, quick tool changes, and compatibility with a wide range of cutters and attachments.Q: How is the milling process controlled on this machine?

A: This model operates manually, with all movements and speed/feed selections managed by the operator through levers and dials. There is no PLC (programmable logic controller) or computerization, allowing for direct control and adaptability during complex or custom milling tasks.Q: What maintenance is required to ensure optimal performance?

A: Regular checks of lubrication, feed mechanisms, V-belt condition, and spindle alignment are recommended. The coolant system, driven by a dedicated 0.15 HP motor, should also be maintained to ensure smooth operation and prevent overheating during prolonged milling.Q: What are the key advantages of using a manual universal milling machine like the Gambin 1m compared to CNC machines?

A: Manual universal milling machines like the Gambin 1m offer greater flexibility for custom or small-batch work, enable skilled machinists to directly control all aspects of the process, and are often more cost-effective for shops that do not require automation. They are also ideal for education, prototyping, and repair jobs.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Tos Fnk 25 Milling Machine 3

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Rigidity : High

PLC Control : No

Dimension (L*W*H) : 1700 x 1540 x 1770 mm

Xyz Pro 2000 M1tr Turret Dro Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Rigidity : Other, Heavy Duty

PLC Control : No

Dimension (L*W*H) : 1560 x 1700 x 2150 mm

Kearney And Trecker Universal Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Rigidity : Other, High Rigidity, heavy duty casting

PLC Control : No

Dimension (L*W*H) : Approx. 2200 mm x 1700 mm x 1800 mm

Cincinnati Double Spindle Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Rigidity : High

PLC Control : No

Dimension (L*W*H) : 2300 mm x 1800 mm x 1800 mm (approx)

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |