|

Dahlih Mcv 2100 Vmc 1

Dahlih Mcv 2100 Vmc 1 Specification

- Product Type

- Vertical Machining Center (VMC)

- General Use

- Metal Cutting, Milling, Drilling

- Material

- Steel, CI, Non-Ferrous Metals

- Type

- CNC Machine

- Capacity

- Max Loading 1,800 kg

- Weight (kg)

- 13,500 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 30 kVA

- Rigidity

- High

- Voltage

- 220/380 V, 3 Phase

- Motor

- Spindle Motor 15/18.5 kW

- Table Size

- 2,300 x 800 mm

- Spindle Speed

- 6,000 rpm

- Axial Choice

- X/Y/Z Axis

- Dimension (L*W*H)

- 5,060 x 3,150 x 3,400 mm

- Feature

- Heavy-Duty Construction, Precision Machining

- Color

- Standard (White & Blue)

- Rapid Feed Rate (X, Y, Z)

- 20/20/15 m/min

- Travel (X/Y/Z)

- 2,100/850/750 mm

- Cooling Type

- Flood and Through Spindle Cooling

- Lubrication System

- Automatic

- Distance from Spindle Nose to Table

- 200 950 mm

- Spindle Drive Method

- Belt / Direct (Optional)

- Floor Space Required

- 20 m

- Repeatability

- 0.003 mm

- Tool Magazine Capacity

- 24 Tools

- Spindle Taper

- BT50

- Noise Level

- 75 dB

- Air Requirement

- 6 kg/cm

- Control System

- Fanuc / Mitsubishi / Siemens (Option)

- Machine Structure

- Box Type Fully Ribbed Meehanite Casting

- Tool Change Time

- 2.5 sec (Tool to Tool)

- Coolant System

- Yes

- Positioning Accuracy

- 0.005 mm

- ATC Type

- Arm Type

About Dahlih Mcv 2100 Vmc 1

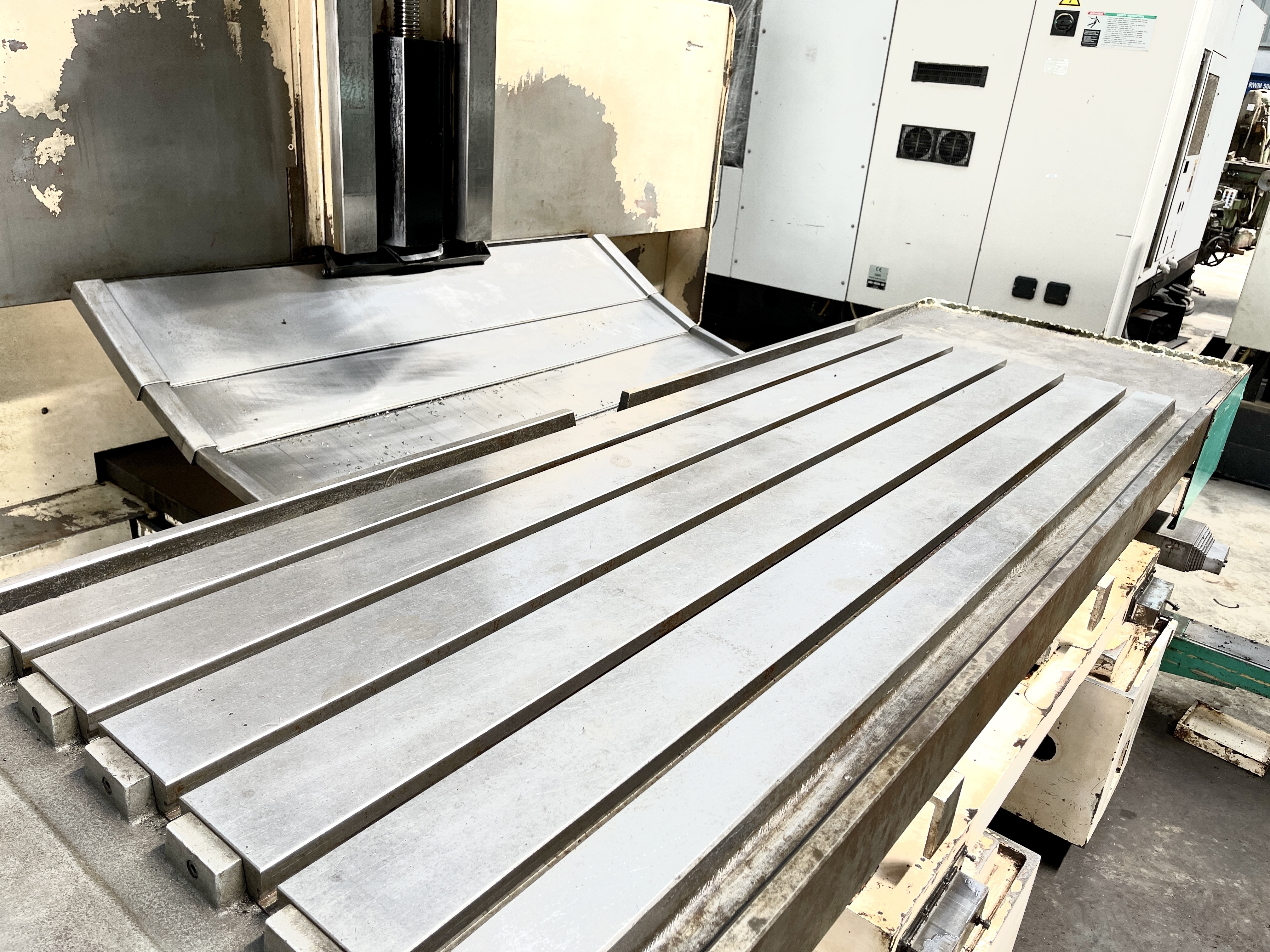

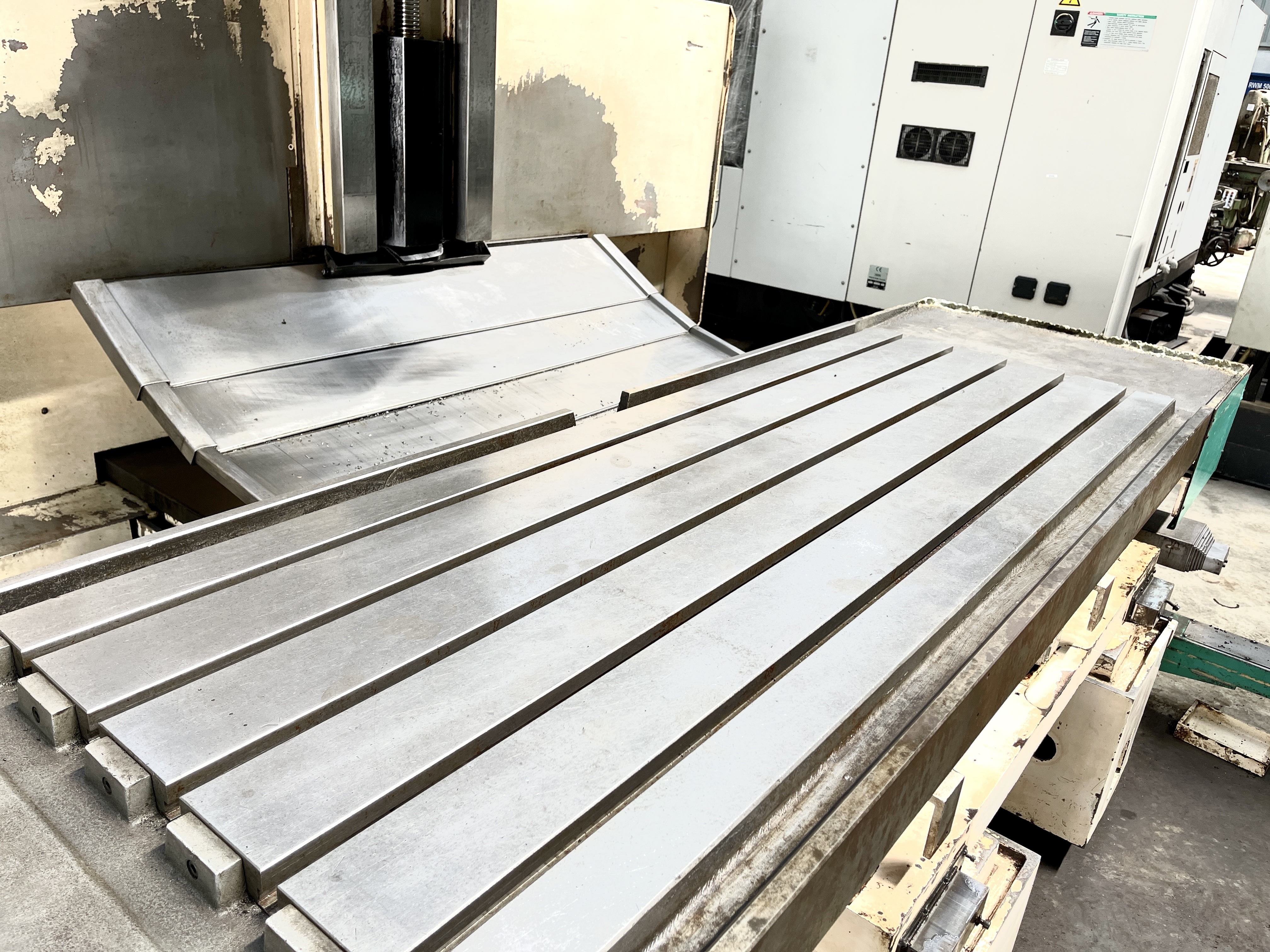

*DAHLIH MCV 2100 VMC #1*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 2100 x 870 x 760 mm

YEAR OF CONSTRUCTION : 1998

Reference No: 2413

Video Link: https://youtu.be/xtdmv2zHV5Y

Technical Specifications:

WORKING CAPACITY

Table Size: 2300 x 970 mm

Travels (XYZ): 2100 x 870 x 760 mm

Guideways: Heavy Box Guides

CNC

Control: Fanuc 18-M (Alpha Drives)

SPINDLE

Spindle Taper: CAT 50

Spindle Speeds: 6000 RPM

ATC

Tool Changer (Arm Type): 29 Stations

Gear Head Spindle

All Covers Available

Robust Structure and High Rigidity

Constructed with a box-type, fully ribbed Meehanite casting, the Dahlih MCV 2100 VMC delivers exceptional rigidity for heavy-duty and high-precision machining. This foundation minimizes vibration and ensures lasting stability, even under substantial loads and intense machining forces, facilitating superior metalworking results.

Advanced Machining Precision

Equipped with high positioning accuracy (0.005 mm) and repeatability (0.003 mm), users can rely on the Dahlih MCV 2100 VMC for intricate, repeatable output across diverse manufacturing jobs. The spindle, available as belt-driven or direct (optional), provides consistent speeds up to 6,000 rpm, catering to a wide range of material requirements.

Efficient Tool Management and Operation

Featuring an arm-type automatic tool changer with a 24-tool magazine, tool changeovers are efficiently completed in just 2.5 seconds. Automated lubrication and advanced flood and through-spindle cooling systems optimize machine performance and ensure longevity in demanding production environments.

FAQ's of Dahlih Mcv 2100 Vmc 1:

Q: How does the Dahlih MCV 2100 VMC 1 support precision machining for industrial applications?

A: With its box-type Meehanite casting and high repeatability (0.003 mm), the machine delivers excellent rigidity and stable performance, allowing users to execute complex metal cutting, milling, and drilling tasks with reliable accuracy required in precision sectors.Q: What materials can be processed using the Dahlih MCV 2100 VMC 1?

A: This CNC machine efficiently handles steel, cast iron, and non-ferrous metals, making it suitable for a wide array of machining operations across automotive, aerospace, and heavy machinery industries.Q: When is the automatic lubrication system activated during operation?

A: The automatic lubrication system is programmed to initiate as needed during machine operation, maintaining all moving components and ensuring uninterrupted, low-maintenance usage for extended production runs.Q: Where is the Dahlih MCV 2100 VMC typically used and installed?

A: It is widely employed in industrial workshops, manufacturing plants, and heavy fabrication units in India and globally, requiring a floor space of approximately 20 m2 for installation and safe operation.Q: What is the process of tool changing and how does it enhance productivity?

A: The machine features an arm-type automatic tool changer that swaps tools within 2.5 seconds (tool to tool), streamlining workflow and minimizing downtime during multi-tool machining operations.Q: How does the cooling system contribute to the quality of finished parts?

A: Utilizing both flood and through spindle cooling, the Dahlih MCV 2100 VMC maintains optimum tool temperatures, prevents heat distortion, and ensures superior surface finishes on processed components.Q: What are the main benefits of using the Dahlih MCV 2100 VMC?

A: Users benefit from its high rigidity, precision machining, large tool storage, fast tool changes, and reliable automated systems, resulting in improved productivity, consistent results, and low operational noise ( 75 dB).

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Fadal 6030 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Other, CNC Controlled

Color : Other, White & Blue

Axial Choice : X/Y/Z

Power Source : Electric

Cincinnati Cfv 550i Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Color : Other, White & Blue

Axial Choice : 3 Axis (X/Y/Z)

Power Source : Electric

Matchmaker 700 Cnc Mill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Color : Other, White & Blue

Axial Choice : 3 Axis (X, Y, Z)

Power Source : Electric

Mori Seiki Cv-500 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Color : Other, Standard Factory Grey

Axial Choice : X, Y, Z

Power Source : Electric

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |