|

Tos Vertical Milling Machine

Tos Vertical Milling Machine Specification

- Product Type

- Vertical Milling Machine

- General Use

- Industrial, Metal Cutting

- Material

- Cast Iron & Steel

- Type

- Universal Milling Machine

- Capacity

- Medium Duty

- Weight (kg)

- 2500 kg

- Computerized

- No

- Automatic

- Semi Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 7.5 HP

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3 Phase Induction

- Table Size

- 1370 mm x 300 mm

- Spindle Speed

- 401800 RPM

- Axial Choice

- 3 Axis

- Dimension (L*W*H)

- 2100 mm x 1700 mm x 2300 mm

- Feature

- Precision, Durable, Reliable

- Color

- Grey

- Feed Range

- 12600 mm/min

- Max. Distance Spindle to Table

- 450 mm

- T-Slot Size

- 16 mm

- Cross Travel (Y)

- 350 mm

- Longitudinal Travel (X)

- 900 mm

- Spindle Taper

- ISO 40

- Coolant System

- Provided

- Condition

- New

- Lubrication System

- Centralized

- Vertical Travel (Z)

- 420 mm

About Tos Vertical Milling Machine

*TOS VERTICAL MILLING MACHINE*

CATEGORY : MILLING MACHINES

CAPACITY : 1250 x 350 mm | ISO 50

Reference No: 1157

Technical Specifications:

Table Size: 1250 x 350 mm

Spindle Taper: ISO 50

Precision Engineering for Industrial Needs

Engineered for accuracy and durability, the Tos Vertical Milling Machine excels in industrial environments where precision metal cutting is essential. Its high-rigidity frame, centralized lubrication system, and advanced feed range enable consistent results, making it ideal for manufacturers requiring sustained reliability and output quality.

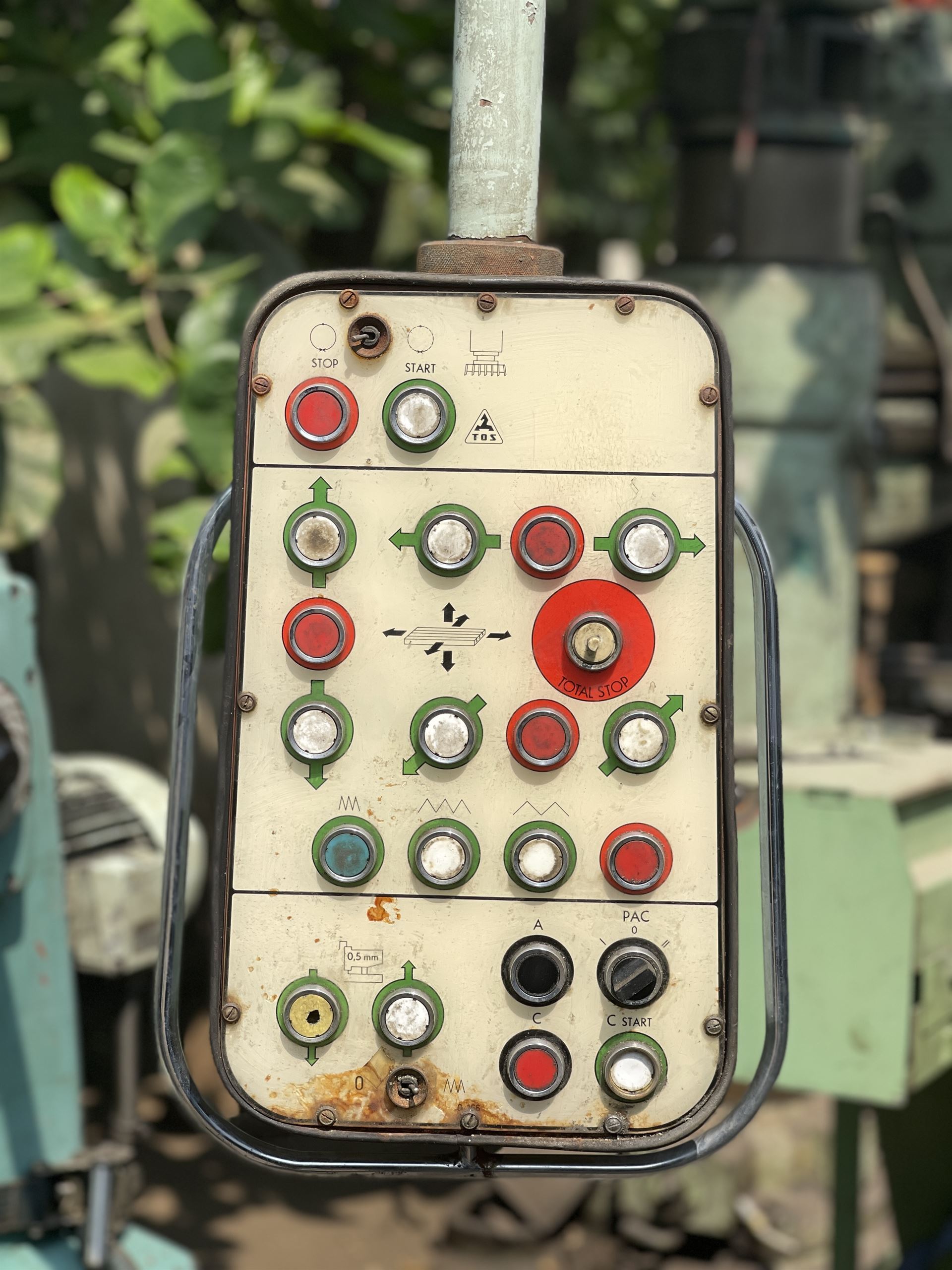

Enhanced Usability and Maintenance

The machine's semi-automatic controls, robust spindle system, and coolant integration ensure ease of use and minimal maintenance. With straightforward adjustments and an intuitive layout, operators can focus on productivity while benefiting from the machine's long-term durability and reduced downtime.

FAQ's of Tos Vertical Milling Machine:

Q: How is the Tos Vertical Milling Machine operated for metal cutting tasks?

A: The Tos Vertical Milling Machine operates on a semi-automatic system using a 3-axis control design. Operators position the workpiece on the 16 mm T-slot table and select the desired feed speed (12-600 mm/min) and spindle speed (40-1800 RPM) to perform a wide range of precision metal cutting operations.Q: What industries most benefit from using this milling machine?

A: This machine is highly beneficial for industrial sectors focusing on metal fabrication, manufacturing, tool-making, and maintenance, especially where precision and medium-duty capacities are required. It serves exporters, importers, suppliers, and traders who demand reliable and consistent milling performance.Q: When is maintenance required and what systems are in place to aid?

A: Routine maintenance is generally suggested after extended periods of use. The machine's centralized lubrication system streamlines regular servicing by automatically delivering lubricant to critical components, thus enhancing operational longevity and reducing manual checks.Q: Where can the Tos Vertical Milling Machine be installed?

A: It is best suited for installation in industrial workshops, manufacturing facilities, and specialized machining centers where its electrical requirements (415 V, 3-phase) and physical dimensions (2100 x 1700 x 2300 mm) can be accommodated safely and efficiently.Q: What process does the machine use for coolant distribution?

A: The integrated coolant system continuously supplies cutting fluid directly to the working area, minimizing tool wear, dissipating heat, and preventing workpiece deformation during prolonged cutting operations.Q: How does this machine improve operational efficiency?

A: The machine's high rigidity, centralized lubrication, and efficient coolant system help maintain stable cutting conditions, reducing downtime and ensuring consistent output, while its medium power consumption (7.5 HP) offers an optimal balance of performance and energy efficiency.Q: What are the key benefits of using this vertical milling machine?

A: Key benefits include high precision, durability, and reliability in metal cutting. Its robust material construction, semi-automatic design, and user-centric features equip manufacturers with a dependable machine for achieving detailed and repeatable cuts in various industrial applications.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Tos Fnk 25 Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Power Consumption : 2.2 kW

Type : Other, Universal

Table Size : 1120 mm x 250 mm

Correa Fu10 Cm125 Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Power Consumption : 7.5 kW

Type : Other, Universal Milling Machine

Table Size : 1250 x 320 mm

Bridgeport M1tr Turret Dro Milling Machine 1

Minimum Order Quantity : 1 Number

Computerized : No

Power Consumption : 3 HP

Type : Other, Vertical Milling Machine

Table Size : 1270 mm x 254 mm

Butler 21 Production Slotter With 45 Rotary Table

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Power Consumption : 5 HP

Type : Other, Horizontal Slotter Machine

Table Size : 450 mm diameter

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |