|

Hitachi Seiki Vs60 Twin Pallet Vmc

Hitachi Seiki Vs60 Twin Pallet Vmc Specification

- Product Type

- Vertical Machining Center (VMC)

- General Use

- Metal machining, Precision parts manufacturing

- Material

- Cast Iron, Steel Structure

- Type

- Twin Pallet VMC

- Capacity

- 700 kg per pallet

- Weight (kg)

- 7000 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 22 kVA

- Rigidity

- High

- Voltage

- 400V / 50Hz / 3 Phase

- Motor

- AC Spindle Motor, 15 kW

- Table Size

- 920 mm x 450 mm (Twin Pallet)

- Spindle Speed

- 10000 RPM

- Axial Choice

- X, Y, Z

- Dimension (L*W*H)

- 2700 mm x 2600 mm x 2550 mm

- Feature

- Twin Pallet system, High Speed, High Precision

- Color

- White & Blue

- Lubrication Type

- Automatic Centralized Lubrication

- Repeatability

- ±0.003 mm

- Travel (X/Y/Z)

- 760 mm / 450 mm / 520 mm

- Chip Conveyor

- Yes

- Pallet Change Time

- 12 seconds

- Positioning Accuracy

- ±0.005 mm

- Controller

- FANUC (0i, 21i, or similar CNC)

- Maximum Tool Diameter / Length

- 80 mm / 300 mm

- Tool Holder Type

- BT40

- Power Requirement

- 3 Phase, 50/60 Hz

- Coolant System

- Equipped

- ATC (Automatic Tool Changer)

- 24 Tools

- Maximum Table Load

- 700 kg

About Hitachi Seiki Vs60 Twin Pallet Vmc

*HITACHI SEIKI VS60 TWIN PALLET VMC*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 1270 x 610 x 450 mm

YEAR OF CONSTRUCTION : 2000

Reference No: 2183

Video Link: https://youtu.be/L63GPSdGI9M

Technical Specifications:

WORKING CAPACITY

Table Size: 1400 x 600 mm

Travels (XYZ): 1270 x 610 x 450 mm

Distance from the table surface to the spindle nose: 200 - 650 mm

Max Table Load: 1000 Kg

Rapid Traverse Rate: X,Y-40 m/min, Z-24m/min

CNC

Control: Fanuc 16iM

SPINDLE

Spindle Taper: CAT50 / BT50 TBC

Spindle Speed: 10000 RPM

Spindle Motor: 22/25 kW

Aprox. Dimensions

Weight: 11 T

Through Spindle Coolant

Twin Pallet Excellence

The Vs60's twin pallet system minimizes downtime and increases productivity by enabling simultaneous loading and machining. Pallet changing occurs in just 12 seconds, allowing high throughput with efficient part handling. This feature makes the machine ideal for industries requiring frequent job changeovers and uninterrupted production cycles.

Superior Precision & Speed

Featuring high rigidity and a cast iron structure, the Vs60 delivers exceptional machining accuracy. It is fitted with a 24-tool automatic changer and runs spindle speeds up to 10,000 RPM. Precision positioning at 0.005 mm and repeatability at 0.003 mm ensure every part meets stringent quality standards for modern manufacturing.

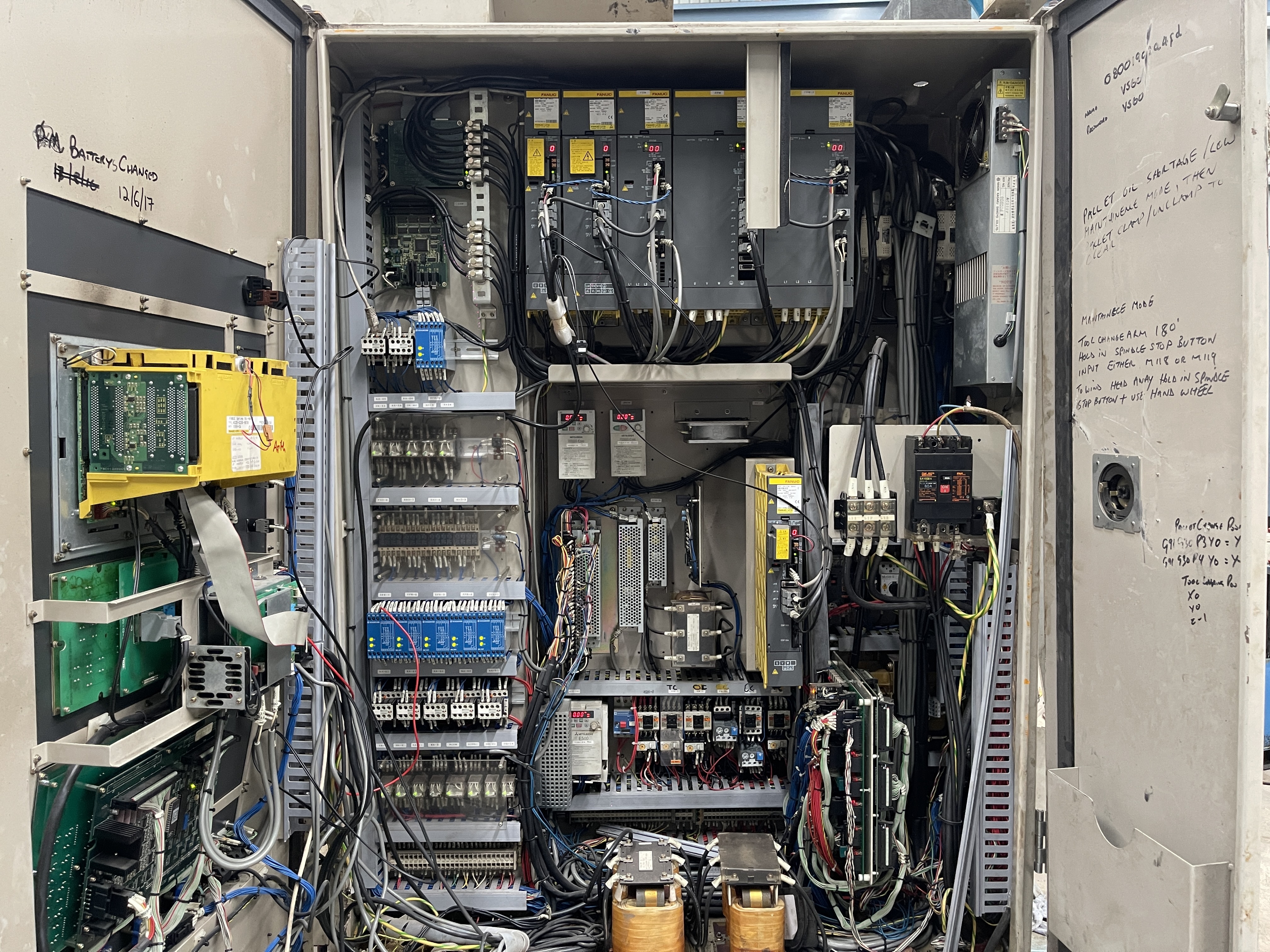

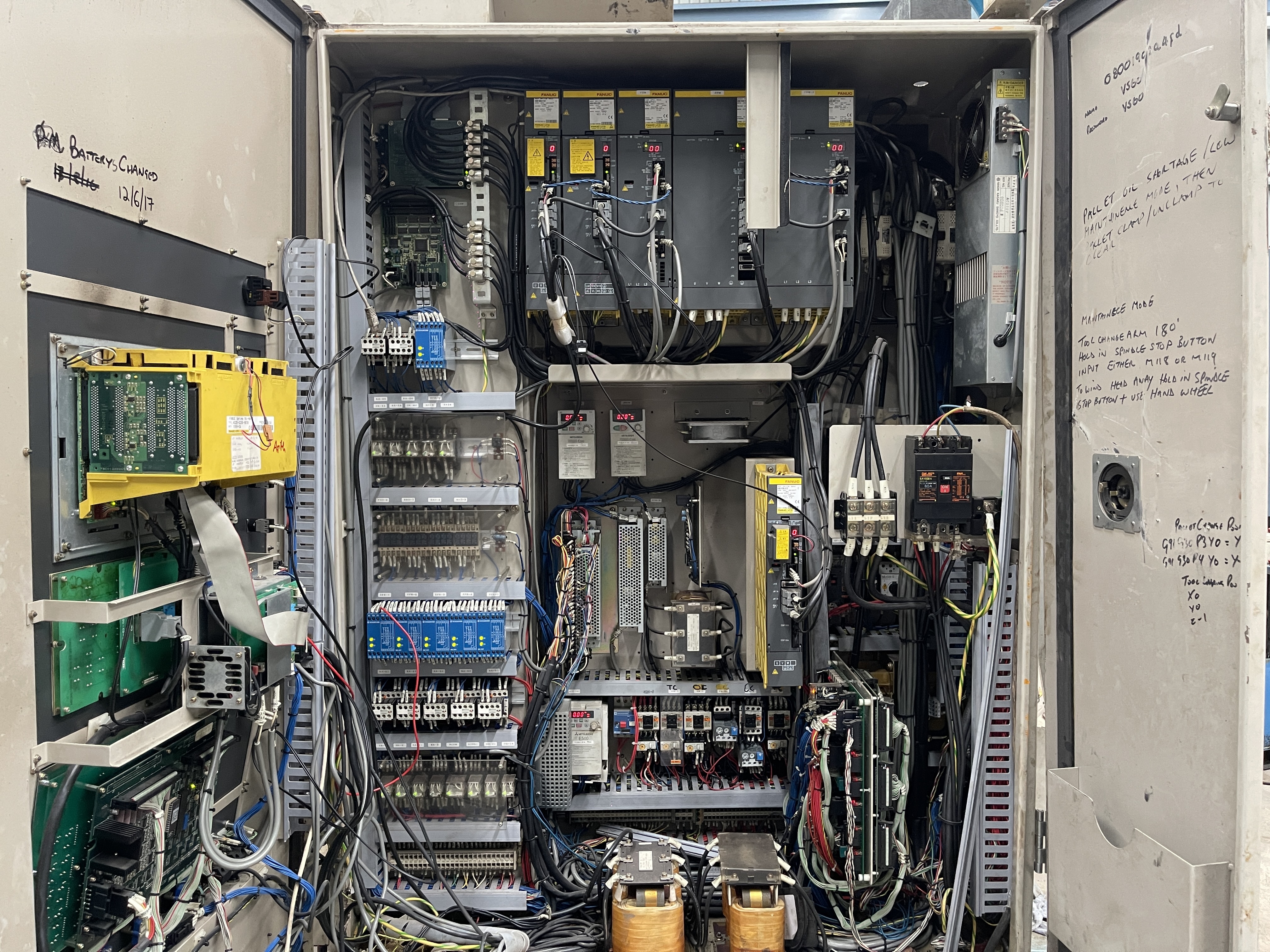

Comprehensive Automation

Equipped with FANUC CNC controls (0i, 21i, or similar) and programmable PLC, the Vs60 offers fully computerized operation. Automatic centralized lubrication and an integrated chip conveyor keep maintenance low, while the coolant system maintains optimal cutting conditions. Its versatile system makes it suitable for a wide range of machining processes.

FAQ's of Hitachi Seiki Vs60 Twin Pallet Vmc:

Q: How does the twin pallet system improve manufacturing efficiency on the Hitachi Seiki Vs60?

A: The twin pallet system enables quick pallet changes-only 12 seconds-reducing idle time between jobs. While one pallet is being machined, the other can be set up, meaning operators can maximize output without stopping for part loading or unloading.Q: What types of materials can be machined on the Vs60 Twin Pallet VMC?

A: The Vs60 is suitable for machining a variety of metals such as cast iron and steel, making it ideal for manufacturing precision parts required in automotive, aerospace, and engineering industries.Q: When is the automatic tool changer utilized and what benefits does it offer?

A: The automatic tool changer, with capacity for 24 tools, is used during multi-operation jobs to switch tools seamlessly during machining. It reduces manual intervention, saves time, and increases overall machining flexibility and accuracy.Q: Where can the Vs60 be installed, and what are its installation requirements?

A: It can be installed in industrial settings such as manufacturing plants, workshops, or CNC job shops. Installation requires a 3-phase power supply (400V/50Hz), sufficient floor space (minimum area: 2700 mm x 2600 mm x 2550 mm), and proper ventilation for optimal operation.Q: What process does the Vs60 use for lubrication and chip management?

A: The Vs60 uses automatic centralized lubrication to ensure precision components remain well-oiled, extending machine life and performance. An integrated chip conveyor automatically removes chips from the machining area, keeping the workspace clean and reducing maintenance.Q: How does the Vs60 maintain high precision during machining?

A: High rigidity, advanced CNC control, precise spindle speed control (up to 10,000 RPM), and accurate feedback mechanisms allow the Vs60 to reach positioning accuracy of 0.005 mm and repeatability of 0.003 mm, maintaining consistent, high-quality results.Q: What are the main benefits of using the Vs60 for precision parts manufacturing?

A: Major benefits include increased throughput from twin pallet automation, high-speed and high-precision machining, flexibility with a 24-tool changer, robust construction for stability, and comprehensive automation. These features combine to deliver efficient and reliable production of complex precision components.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Xyz Krv 2000 Cnc M1tr Turret Milling Machine

Minimum Order Quantity : 1 Number

Type : Other, Turret Milling Machine

Automatic : Other, SemiAutomatic

Axial Choice : X, Y, Z axes

Capacity : Heavy Duty (Max. load 300 kg)

Kitamura Mycenter 2xi Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, CNC Machine

Automatic : Yes

Axial Choice : X/Y/Z

Capacity : Workpiece: Up to 200 kg per pallet

Yang Smt 500 Drill Tap Center (2 Off)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, CNC Drill Tap Center

Automatic : Yes

Axial Choice : 3 Axis

Capacity : 24 Tools ATC

Leadwell 610 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, CNC Vertical Machining Centre

Automatic : Other, Fully Automatic

Axial Choice : XYZ Axis

Capacity : Pallet Maximum Load: 250 kg

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |