|

Alpa Surface Grinder

Alpa Surface Grinder Specification

- Product Type

- Surface Grinder

- General Use

- Precision grinding of flat surfaces

- Material

- Cast Iron Body

- Type

- Horizontal spindle

- Capacity

- Standard

- Weight (kg)

- Approx 1200 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 2.2 kW

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 2 HP

- Table Size

- 225 mm x 450 mm

- Spindle Speed

- 2800 RPM

- Axial Choice

- Manual/Automatic

- Dimension (L*W*H)

- 1600 mm x 1200 mm x 1650 mm

- Feature

- High accuracy, smooth surface finish, robust construction

- Color

- Green

- Maximum Grinding Width

- 225 mm

- Cross Feed Travel

- 225 mm

- Downfeed Graduation

- 0.01 mm

- Lubrication System

- Automatic

- Maximum Grinding Length

- 450 mm

- Grinding Wheel Diameter

- 200 mm

- Work Table Movement

- Longitudinal by Hydraulic, Cross by Hand

- Magnetic Chuck

- Optional

- Coolant System

- Fitted

About Alpa Surface Grinder

*ALPA SURFACE GRINDER*

CATEGORY : SURFACE GRINDERS

CAPACITY : 1600 x 625 x 700 mm

Reference No: 625

Technical Specifications:

WORKING CAPACITY

Travels: 1600 x 625 x 700 mm

Magnet Chuck Equipped: 1520 x 560 mm

Superior Precision for Industrial Needs

Built with a high-rigidity cast iron body, the Alpa Surface Grinder ensures long-lasting structural integrity and reliability. Its downfeed graduation of 0.01 mm allows for ultra-precise adjustments, meeting the demands of industries that require exacting standards. This surface grinder is particularly well-suited for workshops focused on high-accuracy grinding and smooth surface finishes.

Efficient Features & User-Friendly Operation

The machine offers a blend of hydraulic and manual controls, with longitudinal movement powered hydraulically and cross feed by hand. The automatic lubrication and integrated coolant system support extended operation and protect both the workpiece and the machine. Optional magnetic chuck further enhances workpiece handling efficiency and security during grinding operations.

Versatile Application and Robust Construction

Designed for general use in the precision grinding of flat surfaces, this semi-automatic horizontal spindle grinder accommodates a wide range of workpieces up to 225 mm x 450 mm in table size. Its standard capacity, coupled with heavy-duty design and user-friendly controls, makes it a versatile solution for exporters, suppliers, and traders throughout India.

FAQs of Alpa Surface Grinder:

Q: How does the Alpa Surface Grinder ensure high-precision grinding?

A: The Alpa Surface Grinder achieves high-precision grinding through a downfeed graduation of 0.01 mm, a rigid cast iron body to minimize vibration, and a hydraulic longitudinal table movement for steady performance. These features collectively ensure tight tolerances and a superior surface finish.Q: What types of workpieces can be processed with this surface grinder?

A: This machine is tailored for precision grinding of flat surfaces and can handle workpieces up to 225 mm wide and 450 mm long. It is ideal for standard-sized metal or alloy components needing a fine, smooth finish.Q: When should the coolant system and lubrication system be used?

A: Both the coolant system and automatic lubrication operate during all grinding tasks to maintain temperature control, minimize wear, and extend the longevity of both the grinding wheel and the machine components. This ensures optimal performance and surface quality.Q: Where is this surface grinder typically installed and used?

A: The Alpa Surface Grinder is mainly found in industrial workshops, tool rooms, and manufacturing facilities throughout India, especially where high-accuracy flat grinding is regularly required for production or maintenance applications.Q: What is the process for operating the work table movements?

A: Longitudinal table movement is hydraulically driven for consistency, while cross movement is controlled manually, allowing precise positioning by the operator. This twofold mechanism grants flexibility for detailed grinding tasks.Q: How does the optional magnetic chuck benefit the user?

A: Opting for a magnetic chuck improves workpiece stability and makes it easier to secure ferrous materials firmly during grinding, enhancing both safety and accuracy for delicate machining operations.Q: What are the key benefits of choosing this surface grinder for industrial use?

A: Primary advantages include high accuracy, robust construction, smooth finished surfaces, efficient lubrication and cooling, and versatile semi-automatic operation. These qualities deliver reliable performance in demanding grinding environments.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinders Category

Brown Sharpe 618 Hydraulic Surface Grinder 3

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Industrial

Rigidity : Other, Heavy Duty Construction

PLC Control : No

Color : Other, Grey

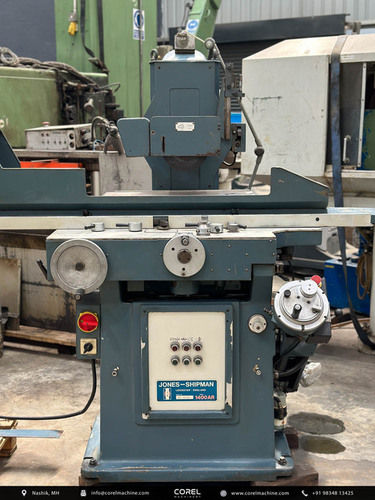

Jones Shipman 1400ar Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Horizontal spindle, reciprocating table

Rigidity : Other, Heavy Duty, Robust Construction

PLC Control : No

Color : Other, Blue/Grey

Jones Shipman 540 Cp Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Hydraulic Surface Grinder

Rigidity : High

PLC Control : No

Color : Other, Grey

Jones Shipman 1400p Surface Grinder 3

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Manual

Rigidity : High

PLC Control : No

Color : Other, Blue / Grey

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |