|

Hardinge C42 Cnc Turning Center

Hardinge C42 Cnc Turning Center Specification

- Product Type

- CNC Turning Center

- General Use

- Metalwork turning operations

- Material

- Cast Iron (structure); Works with metals and alloys

- Type

- Industrial CNC Lathe

- Capacity

- Maximum turning diameter 420 mm

- Weight (kg)

- 4600 kg

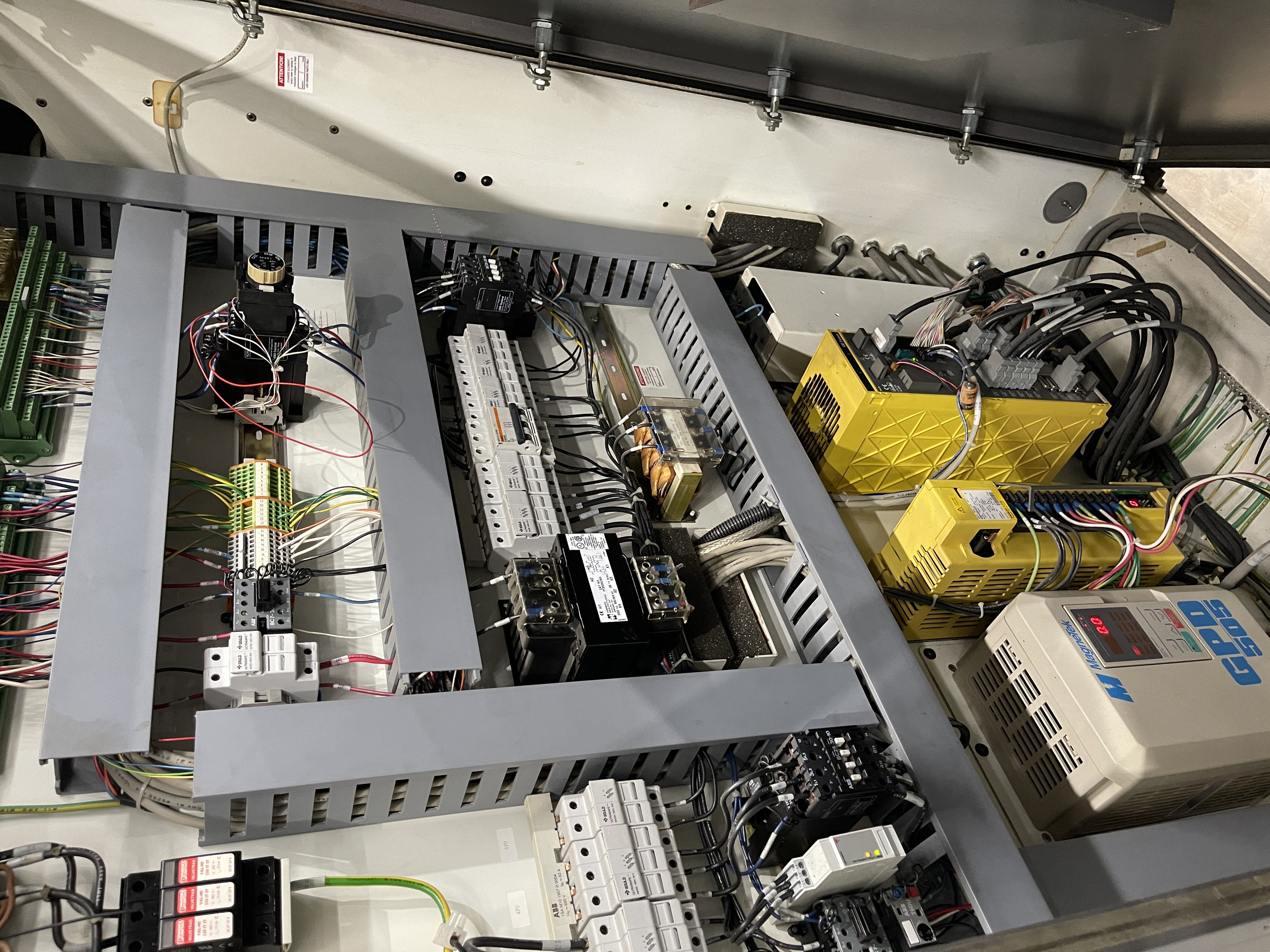

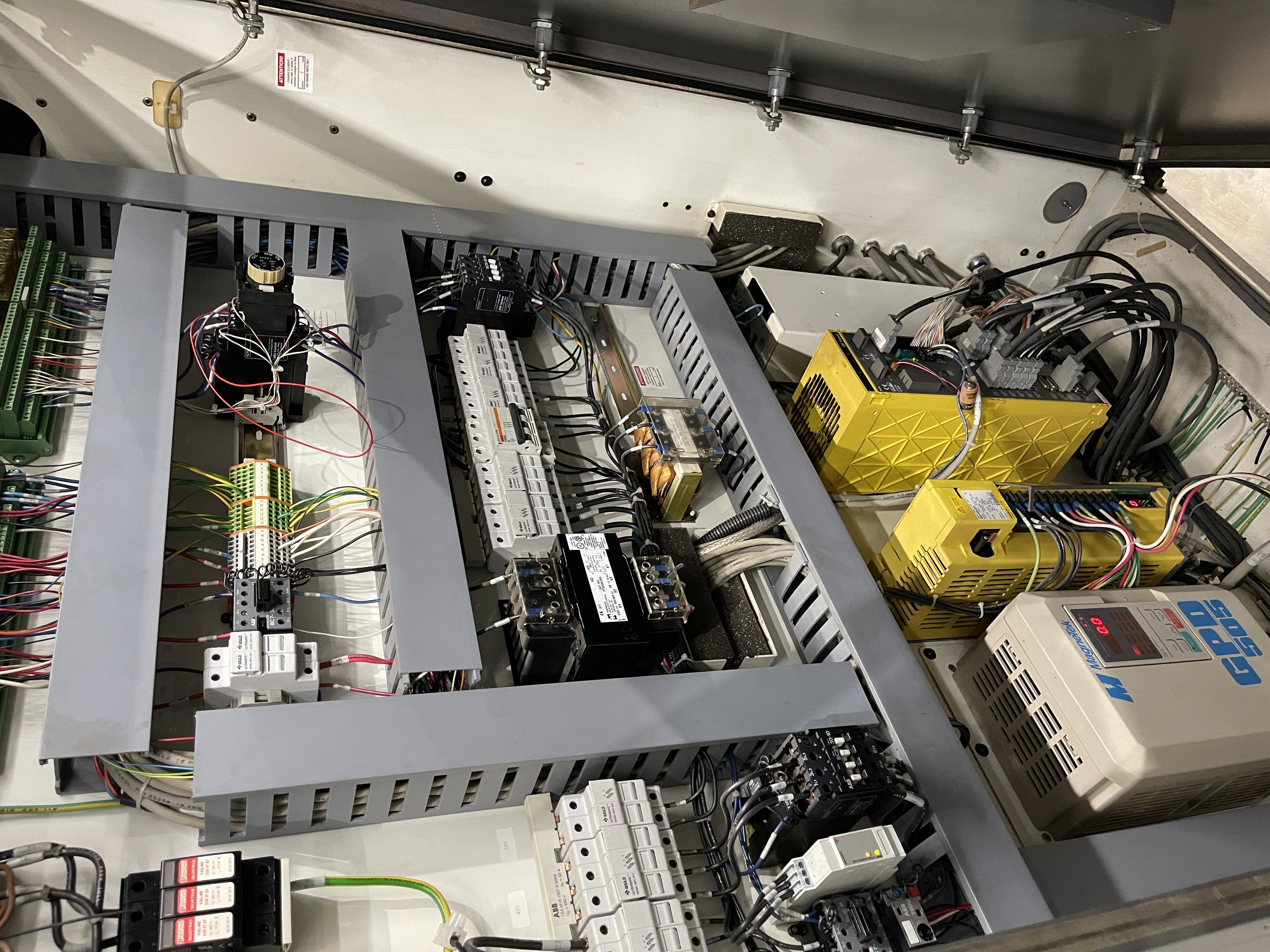

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 30 kVA

- Rigidity

- High rigidity construction

- Voltage

- 400 V, 3 Phase, 50 Hz

- Motor

- High Performance Spindle Motor

- Spindle Speed

- 5000 rpm (max)

- Axial Choice

- Two Axis (X, Z); Optional Y and C axes

- Dimension (L*W*H)

- 2780 x 1900 x 1965 mm

- Feature

- Precision turning, fully computerized, robust

- Color

- Light Grey/White

- Chuck Size

- 210 mm (8 inch)

- Coolant System

- Standard equipped

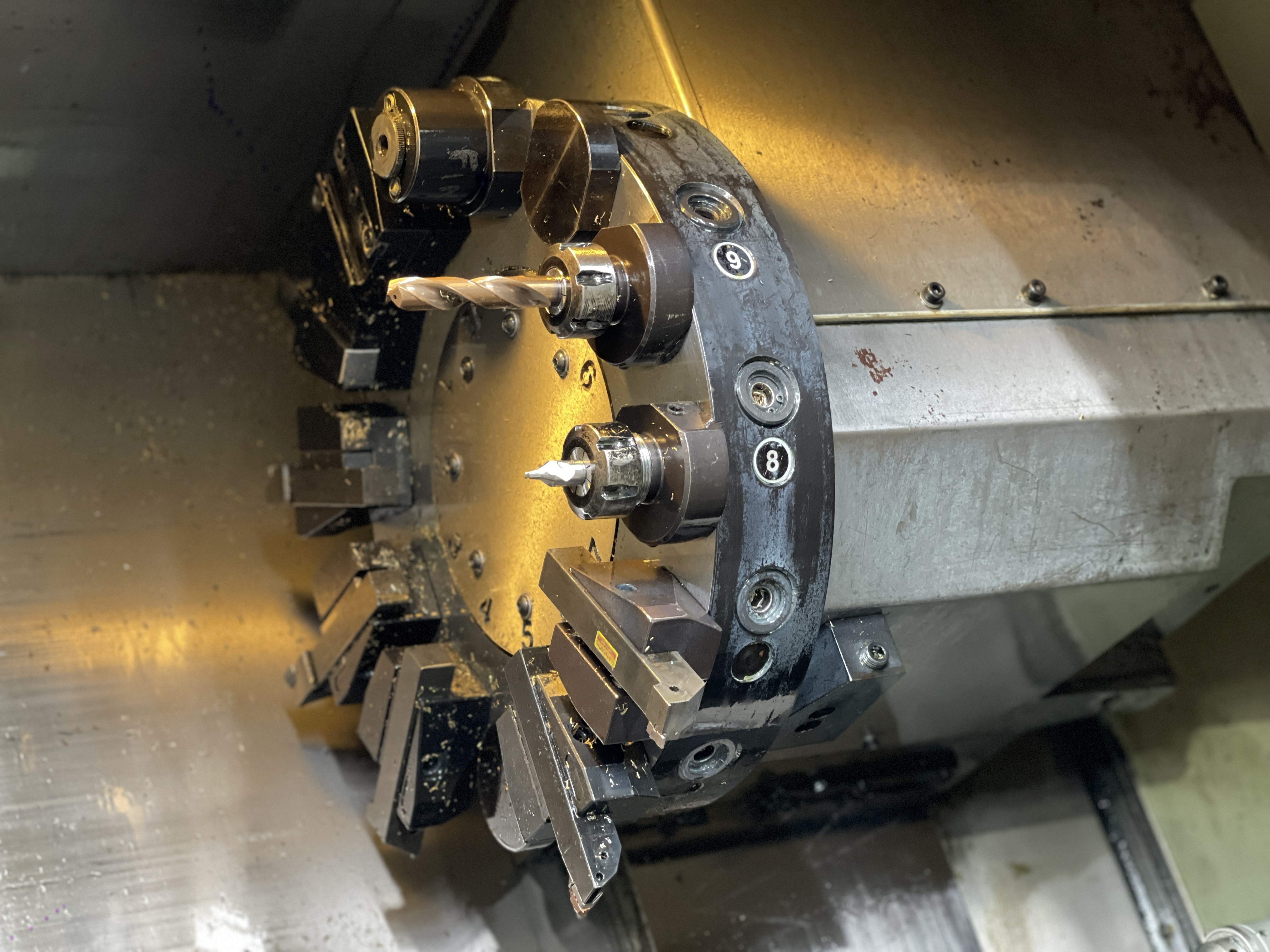

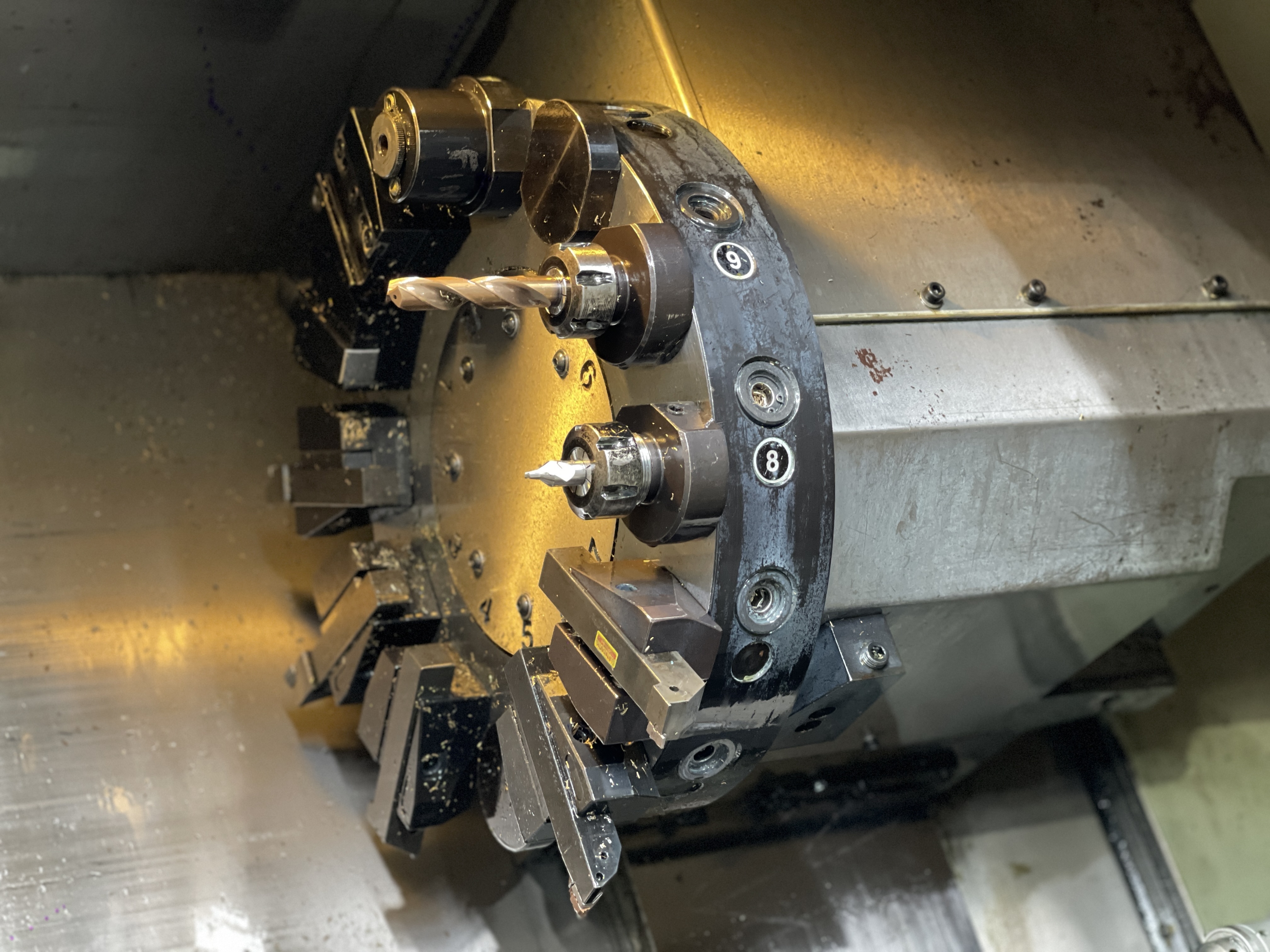

- Tool Turret

- 12 station, VDI 30

- Lubrication

- Automatic centralized lubrication

- Maximum Turning Length

- 610 mm

- Protection

- Full enclosure splash guard

- Operating Temperature

- 5°C to 40°C

- Control System

- Fanuc or Siemens CNC

- Rapid Traverse Rate (X/Z axis)

- 30/30 m/min

- Spindle Bore

- 66 mm

- Swing Over Bed

- 420 mm

- Noise Level

- Below 75 dB

- Tailstock

- Optional

- Hydraulic System

- Integrated for chuck and tailstock

- Positioning Accuracy

- ±0.005 mm

- Repeatability

- ±0.003 mm

About Hardinge C42 Cnc Turning Center

*HARDINGE COBRA 42 CNC TURNING CENTER*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 210 x 350 mm

Reference No: 2970

Video Link: https://youtu.be/E1LrgQpg-kM

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 210 mm

Max Turning Length: 350 mm

Distance Between Centers: 350 mm

Chuck Type: Pneumatic

Travels (X / Z): 197 / 350 mm

CNC

Control: Fanuc 21T (Alpha Drives)

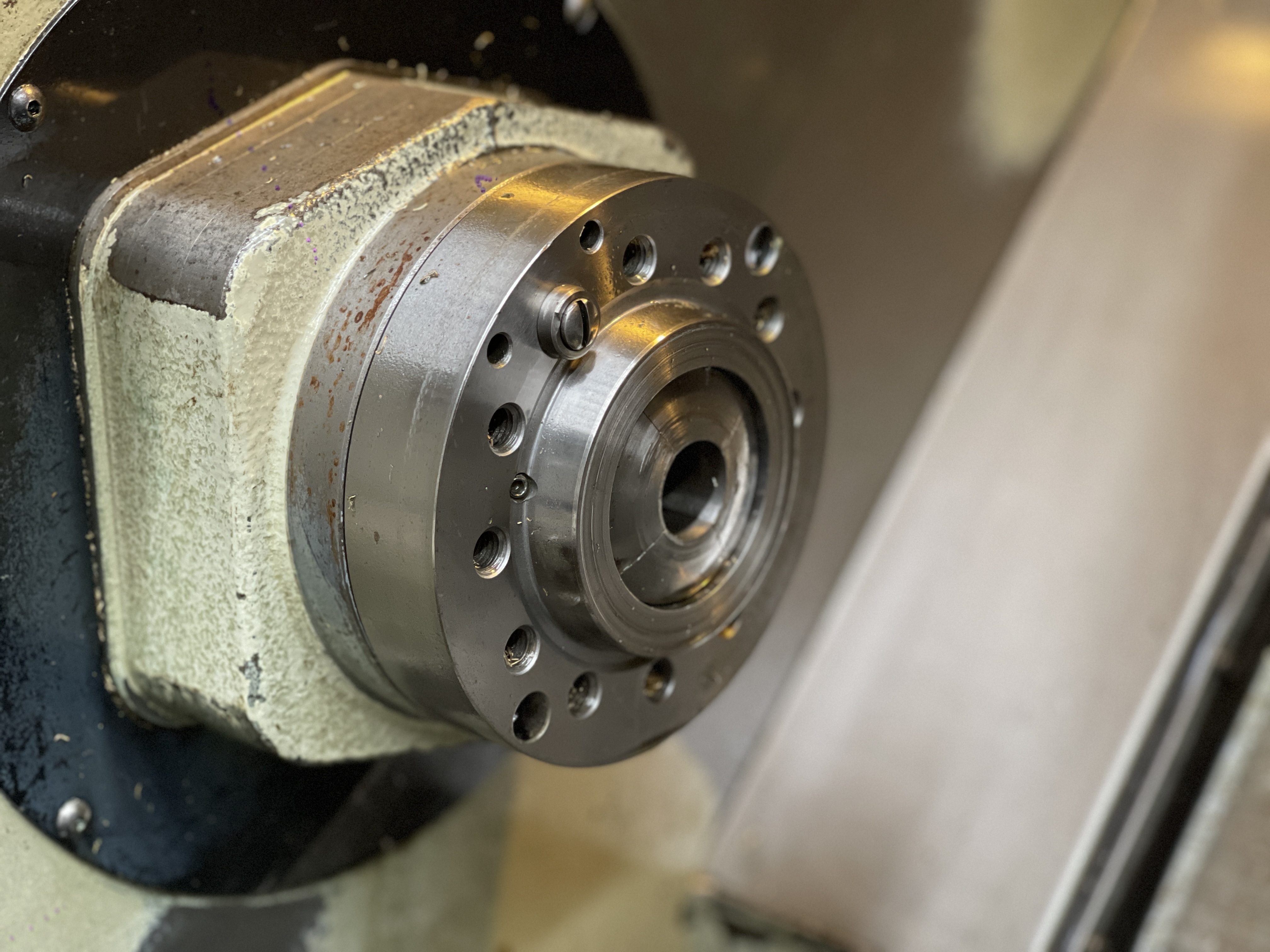

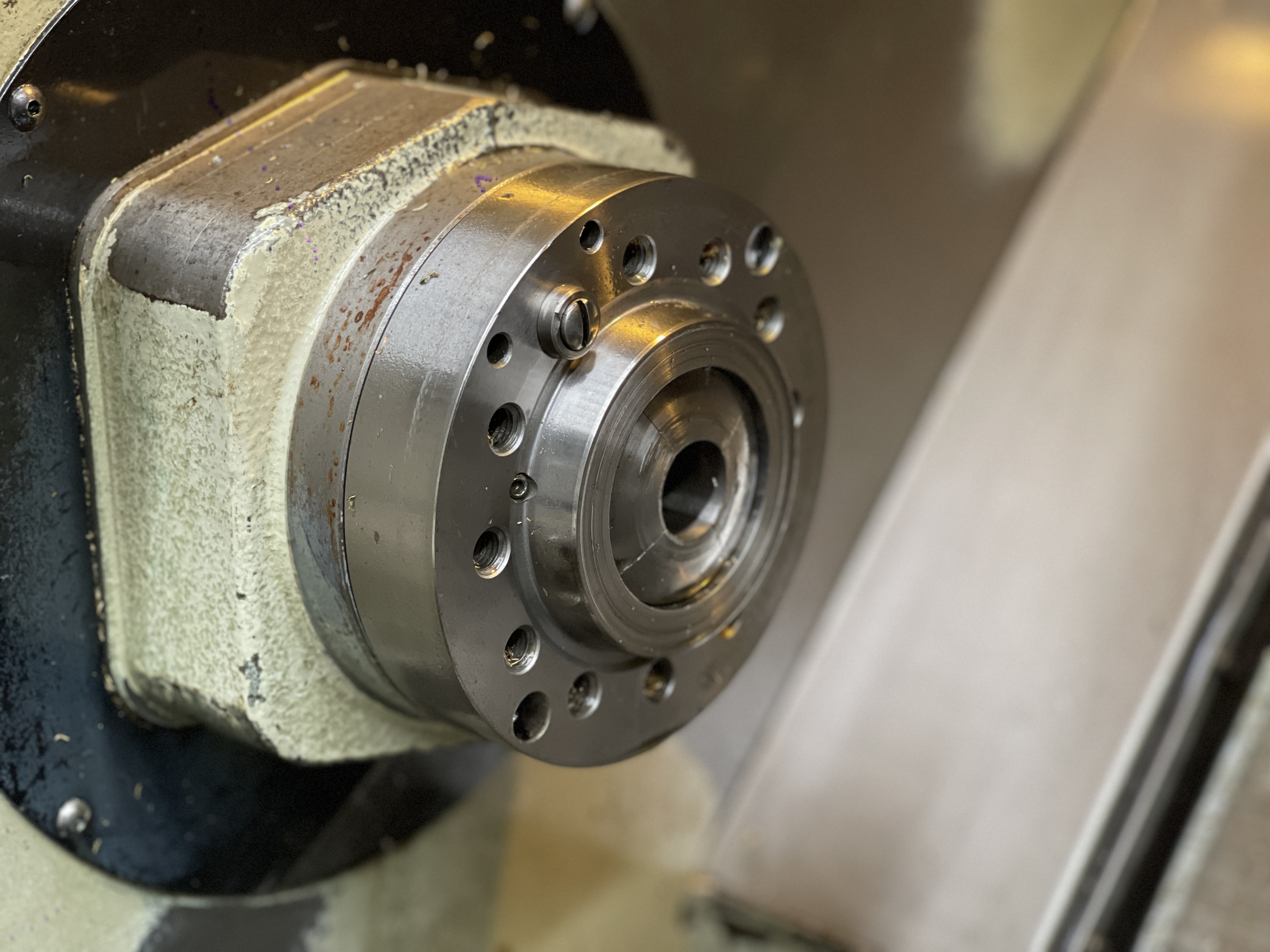

SPINDLE

Spindle Bore: 50 mm

Spindle Nose: A2-5

Spindle RPM: 5000 TBC

Spindle Power: 7.5 / 10 HP

TURRET

Turret: 10 Stations

Precision Engineering for Consistent Results

The Hardinge C42 CNC Turning Center is engineered for maximum reliability and precision. Its robust cast iron body and high-performance spindle motor deliver consistent results, while advanced control systems ensure tight tolerances and high repeatability. Operators can rely on this lathe for demanding industrial applications where accuracy is paramount.

User-Friendly Computerized Control

Featuring Fanuc or Siemens CNC controls, the Hardinge C42 guarantees straightforward programming and operation. The fully computerized system allows for easy adjustments, process monitoring, and integration with PLC. This sets the foundation for automated production, reducing human error and optimizing workflow efficiency in metalworking environments.

Enhanced Safety and Convenience

The machine comes with a full enclosure splash guard, automatic centralized lubrication, and integrated hydraulic systems. These features ensure safe operation, prolonged tool and machine life, and reduced maintenance. Noise levels remain below 75 dB, promoting a comfortable and productive workplace.

FAQ's of Hardinge C42 Cnc Turning Center:

Q: How does the Hardinge C42 CNC Turning Center ensure precise metalworking operations?

A: The Hardinge C42 utilizes high rigidity cast iron construction, a precision spindle motor, computerized Fanuc or Siemens controls, and repeatability of 0.003 mm to consistently deliver accurate and detailed turning results for metal and alloy materials.Q: What are the main benefits of using the Hardinge C42 in industrial applications?

A: Users benefit from fully automated, computerized controls, high speed and accuracy, exceptional reliability, and suitability for heavy-duty turning tasks. Additionally, its robust construction and advanced safety features contribute to prolonged machine life and operator safety.Q: When is the optional tailstock or bar feeder recommended for use?

A: The optional tailstock is ideal for supporting longer workpieces and enhancing stability during extended turning operations, while the bar feeder is recommended for high-volume, continuous production tasks requiring automated material feeding.Q: Where can the Hardinge C42 CNC Turning Center be installed and operated?

A: It is designed for installation in industrial workshops, manufacturing plants, and metalworking facilities in India. The system operates optimally in environments with temperatures from 5C to 40C and requires 400 V, 3 phase, 50 Hz electric supply.Q: What is the process for setting up and programming the Hardinge C42 CNC lathe?

A: Operators use the Fanuc or Siemens control system to input machining parameters, select tooling on the VDI 30 turret, and configure hydraulic and lubrication settings. The system also supports PLC integration for automated sequencing and monitoring.Q: How does automatic lubrication and hydraulic integration benefit operation?

A: Automatic centralized lubrication ensures moving components receive consistent maintenance, reducing downtime and wear. The integrated hydraulic system streamlines chuck and tailstock control, enhancing efficiency and safety during operation.Q: What types of materials can be machined with the Hardinge C42 CNC Turning Center?

A: The machine is designed to work with a wide range of metals and alloys, supporting versatile applications in industrial turning and precision metalwork operations.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

ZPS S-50 CNC Turn Mill Center

Minimum Order Quantity : 1 , , Piece

Color : Other, White & Blue

Automatic : Yes

Type : Other, Horizontal CNC Lathe with Milling Capability

General Use : Metal Machining, Turning, Milling, Drilling, and Tapping

Mori Seiki Sl 5h CNC Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, WhiteGrey

Automatic : Other, Fully Automatic

Type : Other, Horizontal Lathe

General Use : Industrial Turning Operations

Daewoo Doosan Puma 250b Cnc Lathe 2

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Standard Industrial Grey/White

Automatic : Yes

Type : Other, Horizontal Lathe

General Use : Metal Turning, Industrial Machining

Nakamura Tome Superturn 4 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, White & Blue

Automatic : Yes

Type : Other, Horizontal CNC Lathe

General Use : Precision turning of metal components

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |