|

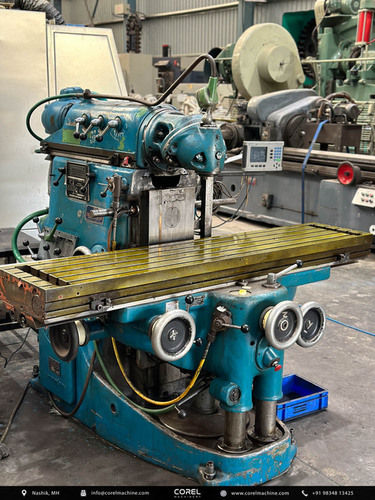

Bridgeport M1tr Turret Dro Milling Machine 1

Bridgeport M1tr Turret Dro Milling Machine 1 Specification

- Product Type

- Turret DRO Milling Machine

- General Use

- Industrial / Workshop Milling Operations

- Material

- Cast Iron Body

- Type

- Vertical Milling Machine

- Capacity

- Table Load 200 kg

- Weight (kg)

- Approx. 1200 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 3 HP

- Rigidity

- High

- Voltage

- 220/440 V

- Motor

- 3 HP Geared Motor

- Table Size

- 1270 mm x 254 mm

- Spindle Speed

- 604200 RPM

- Axial Choice

- X, Y, Z

- Dimension (L*W*H)

- 1700 mm x 1650 mm x 2100 mm

- Feature

- Digital Read Out (DRO), Swiveling Head, Rigid Design, Precision Ball Lead Screws

- Color

- White & Blue

- Digital Read Out Brand

- Mitutoyo/Fagor (as per availability)

- Head Swivel

- 360°

- Table Feed

- Automatic and Manual

- Vertical Travel (Z)

- 400 mm

- Number of T-slots

- 3

- Longitudinal Travel (X)

- 900 mm

- Cross Travel (Y)

- 350 mm

- Coolant Pump

- Yes

- T-slot Size

- 16 mm

- Quill Travel

- 127 mm

- Spindle Motor Drive

- Variable Frequency Drive (VFD)

- Lubrication System

- Centralized

- Spindle Taper

- R8

About Bridgeport M1tr Turret Dro Milling Machine 1

*BRIDGEPORT M1TR TURRET DRO MILLING MACHINE 1*

CATEGORY : MILLING MACHINES

CAPACITY : 1065 x 230 mm

Reference No: 3034

Video Link: https://youtu.be/tGJjrFYAQrs

Technical Specifications:

Table Size: 1065 x 230 mm

Motorized Feed Travel in Longitudinal Travels

Precision and Versatility in Machining

Engineered for accuracy, the Bridgeport M1tr ensures precise cuts with its R8 spindle taper and precision ball lead screws. Its high rigidity frame minimizes vibration, allowing smooth operation over 900 mm X-axis travel, 350 mm Y-axis, and 400 mm Z-axis. The swiveling head supports complex angular machining, while the digital readout system guarantees repeatability and efficient setup for a variety of milling operations.

User-Friendly Features and Construction

Designed with operator convenience in mind, this machine boasts both automatic and manual table feeds, a 360 head swivel, and a centralized lubrication system. The robust cast iron construction supports a 200 kg table load and offers long-term stability. Its 3 HP motor enables strong, variable-speed spindle performance to suit diverse application needs in workshops or industrial settings.

FAQ's of Bridgeport M1tr Turret Dro Milling Machine 1:

Q: How can the Bridgeport M1tr Turret DRO Milling Machine be utilized effectively in an industrial setting?

A: To maximize efficiency, utilize both the automatic and manual table feeds for different milling tasks, leverage the 3-axis digital readout for accurate measurements, and benefit from the 360 swiveling head for complex part machining. Its rigid cast iron construction and precision ball screws ensure consistent performance during heavy-duty operations.Q: What are the main benefits of the digital readout (DRO) system supplied with this machine?

A: The digital readout (DRO), provided in brands like Mitutoyo or Fagor (as available), enables precise tracking of X, Y, and Z axis positioning. This feature simplifies complex milling setups, enhances accuracy, reduces measurement errors, and significantly boosts productivity and repeatability in workshop environments.Q: When is it necessary to use the coolant pump and centralized lubrication system during milling operations?

A: The coolant pump should be activated during prolonged or high-speed milling to dissipate heat and protect tools and workpieces. The centralized lubrication system should operate regularly to keep all moving parts properly lubricated, ensuring smooth function and extending machine life, especially during intensive use.Q: Where is this milling machine best applied in terms of industry or task?

A: This Bridgeport model excels in industrial and workshop environments requiring precise vertical milling, including fabrication shops, tool rooms, maintenance departments, and manufacturing units. It's ideal for applications involving precision metalworking, prototyping, and general machining tasks.Q: What process should be followed for adjusting the spindle speed and direction on this machine?

A: Users can adjust spindle speed across 60-4200 RPM using the variable frequency drive (VFD), which allows fine control via the user interface. The spindle direction can be set according to the requirement of the milling operation, ensuring versatility for a wide range of materials and cutting conditions.Q: How does the machine ensure high accuracy and rigidity during operation?

A: With its high-rigidity cast iron body, precision ball lead screws on all axes, and a robust geared spindle drive, the machine minimizes deflection and vibration. This setup ensures accurate and stable performance even under heavy loads or during extended cutting operations. The digital readout system further enhances machining accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Cincinnati Double Spindle Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Material : Other, Cast Iron & Steel

Weight (kg) : Approx. 2800 kg

Rigidity : High

Butler Elgamill Cs 10va Bed Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Material : Other, Cast Iron & Steel

Weight (kg) : Approx. 14000 kg

Rigidity : High

Kearney And Trecker Universal Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Material : Other, Cast Iron body with hardened steel gears

Weight (kg) : Approx. 2700 3200 kg

Rigidity : Other, High Rigidity, heavy duty casting

Huron Ku6 Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Material : Other, Cast Iron

Weight (kg) : 6000 kg

Rigidity : High

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |