|

Mazak Variaxis 500-5x 5 Axis Twin Pallet Vmc (Transit)

Mazak Variaxis 500-5x 5 Axis Twin Pallet Vmc (Transit) Specification

- Product Type

- Vertical Machining Center (VMC)

- General Use

- Precision Machining for Die, Mold, Aerospace, Medical Industries

- Material

- Cast Iron Base & Structure

- Type

- Twin Pallet Machining Center

- Capacity

- 500 kg (per pallet)

- Weight (kg)

- 8,000 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes (MAZATROL CNC System)

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 22 kVA

- Rigidity

- High

- Voltage

- 220-415 V

- Motor

- Main Spindle Motor 18.5/15 kW (30 min/cont.)

- Table Size

- 500 mm diameter (pallet)

- Spindle Speed

- 12,000 rpm

- Axial Choice

- 5 Axis (X,Y,Z,B,C)

- Dimension (L*W*H)

- 3,000 x 3,040 x 2,940 mm

- Feature

- Twin Pallet, Simultaneous 5 Axis Machining, High Accuracy

- Color

- White/Grey

- Number of Pallets

- 2 (Twin Pallet)

- C Axis Rotation

- 360 Degrees

- Application

- Aerospace, Medical, Automotive Precision Parts Machining

- Repeatability

- ±0.002 mm

- X Axis Travel

- 510 mm

- Tool Storage Capacity

- 30 Tools (ATC)

- Y Axis Travel

- 510 mm

- A Axis Rotation

- -120 to +30 Degrees

- Control System

- Mazak Mazatrol Matrix

- Chip Conveyor

- Yes, Standard

- Positioning Accuracy

- ±0.003 mm

- Automatic Tool Changer

- Yes

- Z Axis Travel

- 510 mm

- Maximum Load per Pallet

- 200 kg

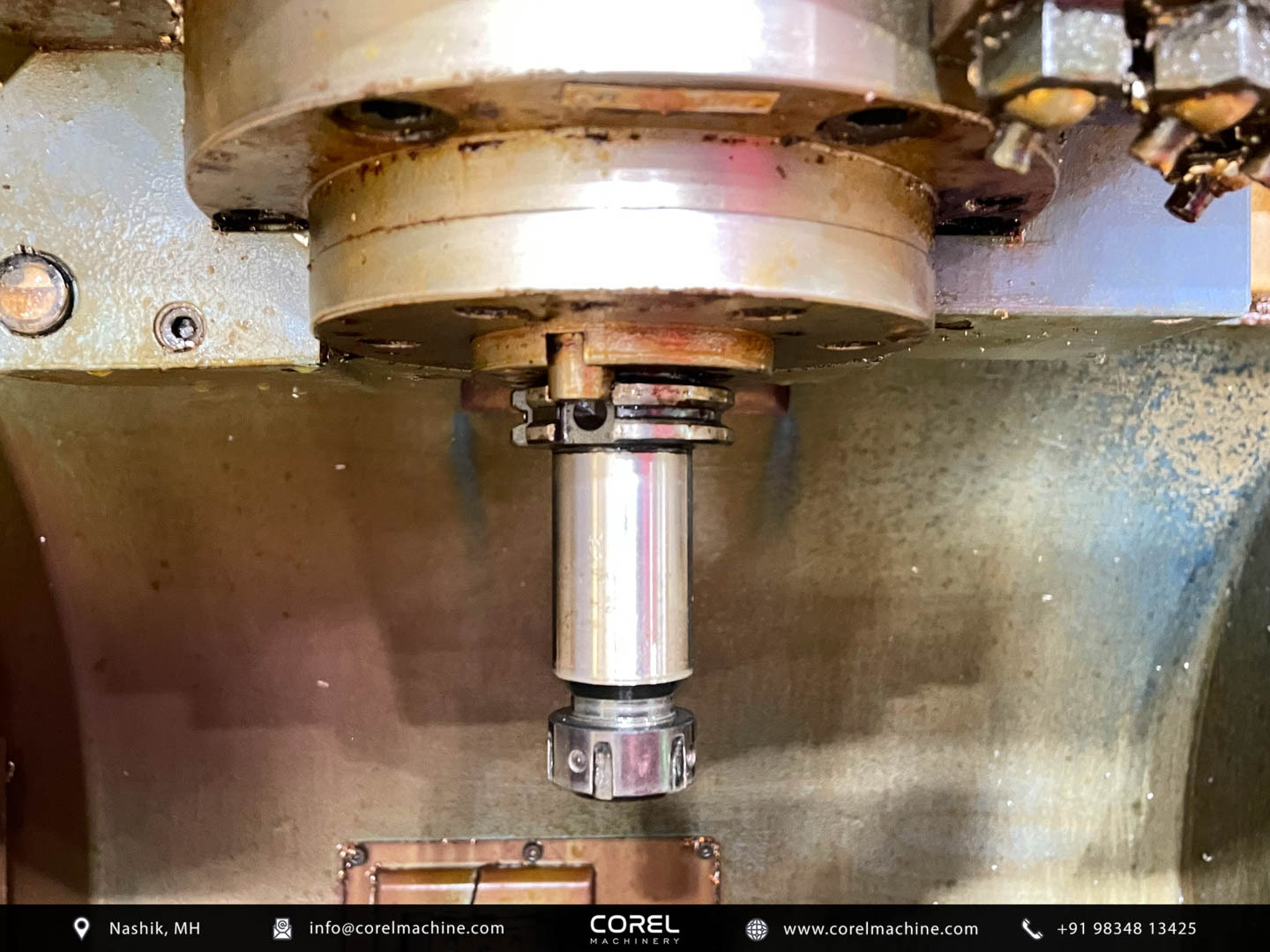

- Spindle Taper

- BT40

- Coolant System

- Through Spindle Coolant

- Rapid Traverse Rate (X/Y/Z)

- 42 m/min

- Air Supply Requirement

- 0.5 MPa (5 bar)

About Mazak Variaxis 500-5x 5 Axis Twin Pallet Vmc (Transit)

*MAZAK VARIAXIS 500-5X 5 AXIS TWIN PALLET VMC (TRANSIT)*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 510 x 510 x 460 mm

YEAR OF CONSTRUCTION : 2003

Reference No: 3877

Video Link: https://corelmachine.com/wp-content/uploads/2023/03/Mazak-Variaxis-Corel-Video.mov

Technical Specifications:

WORKING CAPACITY

Travels (XYZ): 510 x 510 x 460 mm

A Axis: -120 / +30 Deg

C Axis: 0.001 Deg

Pallet Size: 500 x 400 mm

Max Workpiece Size: 500 Dia x 405 High

Max Workpiece Weight: 300 Kgs

CNC

Control: Mazatrol 640M

SPINDLE

Spindle Speeds: 12000 RPM (TBC)

Twin Pallet

High-Performance 5-Axis Machining

Achieve intricate geometries and tight tolerances with the Mazak Variaxis 500-5xs simultaneous 5-axis machining. Its robust cast iron base and highly rigid construction make it the machine of choice for critical applications in aerospace, medical, and automotive industries.

Boost Productivity with Twin Pallet System

The integrated twin pallet system facilitates efficient workpiece loading and unloading, reducing idle times and maximizing operational throughput. Each pallet supports loads up to 200 kg, allowing production flexibility for multiple component types.

Precision and Reliability Assured

With rapid traverse rates up to 42 m/min, positioning accuracy of 0.003 mm, and repeatability of 0.002 mm, this VMC excels in tasks demanding the highest level of precision. Advanced coolant and chip management systems ensure smooth, uninterrupted operation.

FAQs of Mazak Variaxis 500-5x 5 Axis Twin Pallet Vmc (Transit):

Q: How does the twin pallet system enhance production efficiency?

A: The twin pallet system enables operators to load or unload workpieces on one pallet while the machine continues machining on the other. This significantly reduces downtime and improves overall productivity by streamlining the workflow.Q: What types of parts and industries is the Mazak Variaxis 500-5x best suited for?

A: This VMC is designed for high-precision machining of components in aerospace, medical, die and mold, and automotive sectors. Its ideal for complex geometries and tight tolerances frequently required in these industries.Q: Where can the Mazak Variaxis 500-5x be installed and operated?

A: The machine is suitable for installation in industrial manufacturing facilities with access to a 220-415 V power source and a stable 0.5 MPa (5 bar) air supply. Its compact footprint (3,000 x 3,040 x 2,940 mm) supports a wide range of shop environments.Q: What process control and automation features does this VMC offer?

A: Equipped with the Mazak Mazatrol Matrix CNC system, users benefit from user-friendly controls, PLC automation, and computerized operations. The 30-tool ATC and chip conveyor further support automated workflows and minimized manual intervention.Q: When is through spindle coolant particularly advantageous?

A: Through spindle coolant is especially beneficial during deep drilling and high-speed machining, helping to extend tool life, maintain tight tolerances, and remove chips efficiently from the work area to enhance surface finishes.Q: What is the maximum weight capacity per pallet, and how does it impact machining?

A: Each pallet can support up to 200 kg, allowing the machining of heavy or multiple parts in a single setup. This capacity ensures versatility for larger or batch-production applications while maintaining stability during operation.Q: What are the main benefits of choosing the Mazak Variaxis 500-5x for precision machining?

A: The main benefits include simultaneous 5-axis machining for complex parts, high accuracy and repeatability, automated twin pallet system for continuous operation, robust construction, and advanced control systemsresulting in greater productivity and superior part quality.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Daewoo Doosan Mynx 540 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, CNC Vertical Machining Center

Computerized : Yes

Power Source : Electric

Voltage : 380 415 V

Cincinnati Cfv 550i Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, CNC Machining Center

Computerized : Yes

Power Source : Electric

Voltage : 415 V

Daewoo Doosan Dmv 4020/50 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, CNC VMC

Computerized : Yes

Power Source : Electric

Voltage : 220/380/415V, 3 Phase

Mori Seiki Cv-500 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Twin Pallet VMC

Computerized : Yes

Power Source : Electric

Voltage : 220 V / 3 Phase

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |