|

Microsprint 50

Microsprint 50 Specification

- Product Type

- Bar Feeder

- General Use

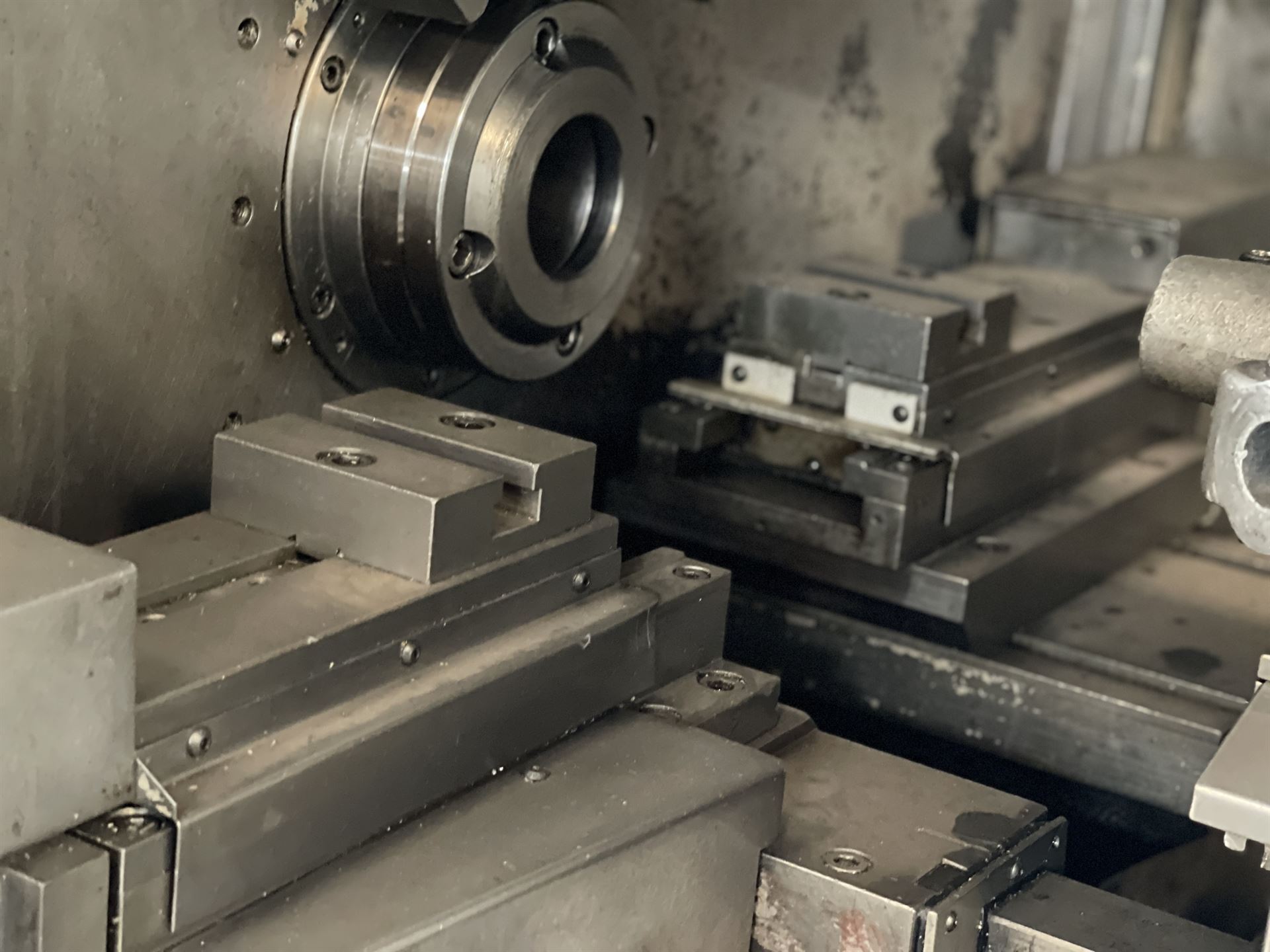

- For feeding bars automatically into CNC/Automatic lathes

- Material

- Steel Construction

- Type

- Automatic Bar Feeding Equipment

- Capacity

- Bar diameter 5 mm 50 mm

- Weight (kg)

- 340 kg

- Computerized

- No

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Yes

- Power Source

- Electric

- Power Consumption

- 0.55 kW

- Rigidity

- High

- Voltage

- 230V

- Motor

- Induction Motor

- Table Size

- 500 mm

- Spindle Speed

- Up to 6000 RPM

- Axial Choice

- Single and Multiple Axial Option

- Dimension (L*W*H)

- 2050 x 390 x 1050 mm

- Feature

- Quick Change Over, Compact Design, Low Maintenance

- Color

- Green / White

- Noise Level

- Low Noise Operation

- Drive System

- AC Servo Motor

- Guide Channel

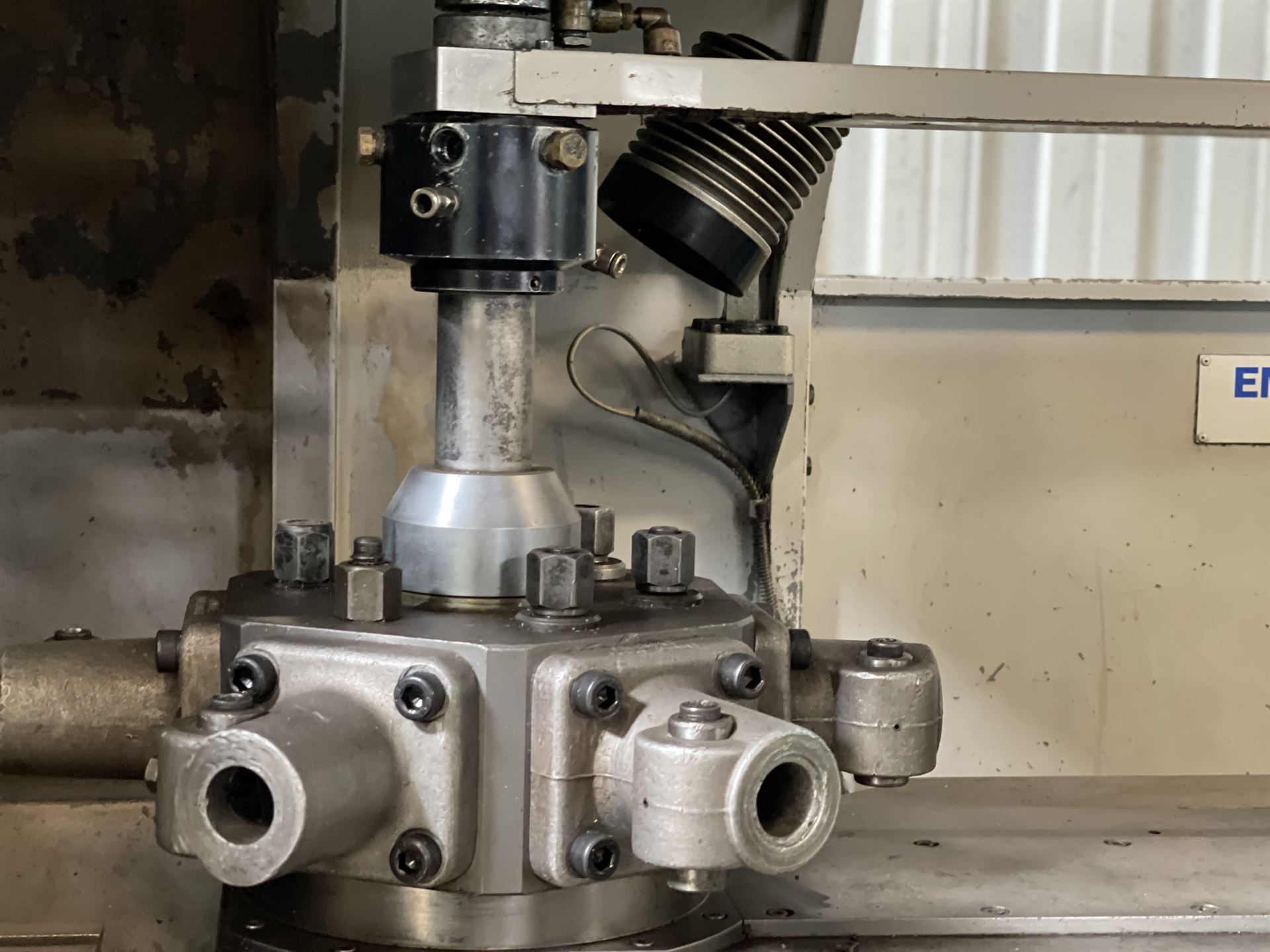

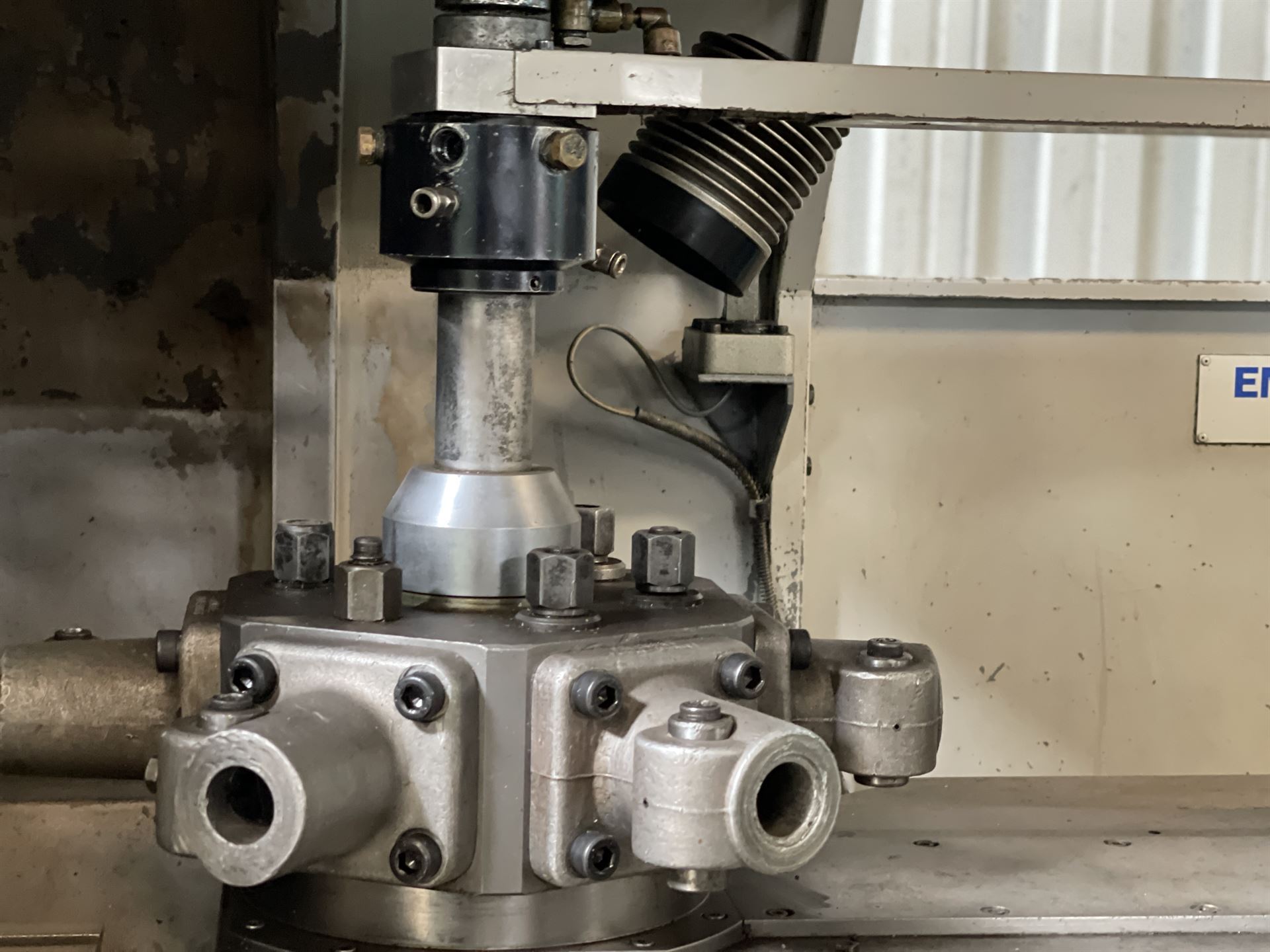

- Vibration Absorption Polyurethane

- Bar Alignment

- Automatic Centering

- Bar Change Time

- Less than 1 Minute

- Lubrication

- Centralized Lubrication System

- Bar Loading

- Manual/Automatic

- Control Panel

- User Friendly Microprocessor Based Panel

- Supported Lathe Types

- CNC & Automatic Lathe Machines

- Suitable Bar Length

- 1000 mm to 3000 mm

- Operating Temperature

- 0°C to 45°C

About Microsprint 50

TECHNICAL SPECIFICATIONS

| Work capacity

Headstock

Spindle drive

|

Efficient Bar Handling for CNC Lathes

Microsprint 50 enables seamless automatic feeding of bars into CNC and automatic lathes, maximizing productivity. Its quick changeover feature and centralized lubrication system ensure high uptime and minimal operator intervention, making it ideal for modern machining environments where speed and reliability are essential.

Advanced Drive and Control

Powered by an AC servo motor and supported by a user-friendly microprocessor control panel, the Microsprint 50 guarantees precise and stable bar alignment. The automatic centering mechanism and PLC controls allow for versatile operation and facilitate quick adjustments, even for complex production runs.

Low Noise and High Stability

The vibration-absorbing polyurethane guide channel ensures low-noise operation while maintaining the feeder's high rigidity. Its robust steel construction and compact footprint of 2050 x 390 x 1050 mm make it a practical choice for workshops requiring both quiet and reliable performance.

FAQ's of Microsprint 50:

Q: How does the Microsprint 50 contribute to efficient bar feeding in CNC and automatic lathes?

A: The Microsprint 50 streamlines bar loading through its automatic feeding and quick changeover abilities. With manual or automatic bar loading options and a centralized lubrication system, it supports rapid production cycles, reduces downtime, and minimizes manual effort.Q: What is the process for changing bars with the Microsprint 50?

A: Bar changes can be completed in under one minute, thanks to a user-friendly control panel and an efficient quick changeover mechanism. The system's automatic centering ensures correct alignment with minimal manual intervention, enhancing operational efficiency.Q: When should I use the Microsprint 50 in my manufacturing setup?

A: The Microsprint 50 is best utilized when operating CNC or automatic lathes requiring consistent, automated bar feeding for diameters of 5 mm to 50 mm. Its low noise, rapid transition, and robust construction are particularly valuable in high-throughput environments.Q: Where is the Microsprint 50 typically installed?

A: This equipment is installed alongside CNC and automatic lathe machines in workshops, manufacturing plants, or job shops focused on turning operations. Its compact design allows for integration even in facilities with limited floor space.Q: What are the main benefits of using Microsprint 50?

A: Key benefits include increased production efficiency, reduced manual labor, low operational noise levels, minimized changeover time, enhanced precision with automatic centering, and long-term reliability due to its sturdy steel structure and centralized lubrication.Q: How does the Microsprint 50 maintain operational stability and low noise?

A: It uses a vibration absorption polyurethane guide channel and a high-rigidity steel body, both of which dampen sound and ensure smooth operation, even at spindle speeds up to 6000 RPM.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Mazak F10 Cnc Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Consumption : 34 kVA

Product Type : CNC Vertical Turning Lathe (VTL)

Automatic : Other, Fully Automatic Operation

Power Source : Electric

Nakamura Tome Tmc-4 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Consumption : 7.5 kW

Product Type : CNC Lathe

Automatic : Yes

Power Source : Electric

Mori Seiki Sl-303b/1500 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Consumption : 28 kVA

Product Type : CNC Lathe

Automatic : Other, Fully Automatic

Power Source : Electric

Colchester Tornado 100 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Consumption : 7.5 kW

Product Type : CNC Lathe

Automatic : Yes

Power Source : Electric

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |